Petrol Powered Lawn Mowers

E&OE

©2017 Bäumr-AG

4

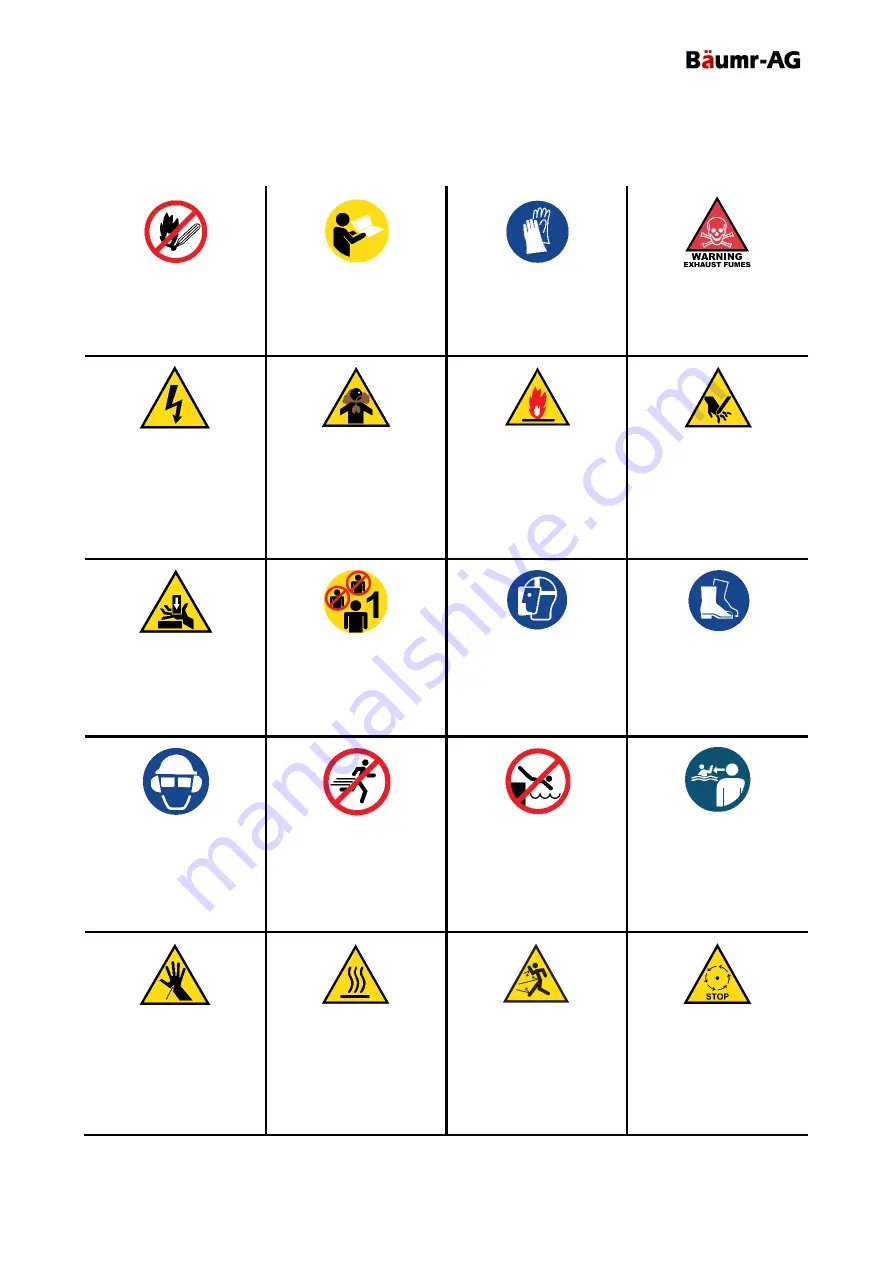

Safety Symbols

The product may have safety warning labels attached to it, explained below. Understand the symbols on

your product and their meanings. If any stickers become unreadable, unattached etc, replace them.

Flammable Material Hazard

Flammable liquids, gases or

substances etc may present.

Avoid ignition sources and

open flames. Danger of fire.

Read User Manual

Read and fully understand

product safety warnings,

operation, procedures etc

before using the product.

Use Hand Protection

Wear appropriate hand

protection and take due care

as the product or use of the

product may present hand

hazards.

Carbon-Monoxide Hazard

Do not use the product in

confined areas or without

adequate ventilation. Carbon-

monoxide poisoning can be

fatal.

Electrocution / Electrical

Shock Hazard

High voltage or high current

electricity may be present or

required by the product. Take

due care when handling

electrical products, cables,

plugs and leads. Electrical

shock can be fatal.

Toxic Fumes hazard

Using the product or by-

products from use may

produce fumes, smoke or

particles that could be harmful

if inhaled. Wear appropriate

breathing protection and have

adequate ventilation.

Explosive Material Hazard

Combustible liquids, gases or

substances etc may be

present. Avoid ignition sources

and open flames. Danger of

explosion.

Cutting / Amputation Hazard

The product may have blades,

edges or mechanical devices

that can cause severe cut

injury to fingers, limbs etc.

Take due care when handling

and using the product.

Crush Hazard

The product may have blades,

edges or mechanical devices

that can cause severe crush

injury to fingers, limbs etc.

Take due care when handling

and using the product.

Single Operator Only

The product must be operated

by a single person only. More

than one person operating the

product may introduce

additional hazards.

Use Face Protection

Wear appropriate full-face

protection and take due care

as the product or use of the

product may present face and

eye hazards.

Use Foot Protection

Wear appropriate foot

protection and take due care

as the product or use of the

product may present foot

hazards.

Use Eye / Ear / Head

Protection

Wear appropriate eye and / or

ear and / or head protection

and take due care as the

product or use of the product

may present eye, hearing and

head hazards.

Running Hazard

Do not run on or near the

product as doing so may

present a fall hazard.

Diving Hazard

Do not dive into the product as

doing so may present a neck /

head injury hazard.

Adult Supervision Required

Always supervise children and

other users of a product to

prevent drowning or injury.

Skin Penetration / Puncture

Hazard

The product may produce

pressure, emit liquids or

objects that can cause severe

injury to fingers, limbs, blood

etc. Take due care when

handling and using the

product.

Hot Surface Hazard

Be aware that the product may

produce high temperatures

and hot surfaces that can

cause burn injuries.

Flying Debris Hazard

Be aware that the product or

use of the product may

present hazards produced by

flying debris. Wear appropriate

clothing and protectiove

devices.

Moving Parts Hazard

Be aware that the product

contains or uses mechanical

devices that move or rotate.

Always wait for moving parts

to stop fully before handling

the product, adjusting,

maintenence etc.