TAM 00609

11

DA 100

– 280

03 / 2015

Three phase asynchronous motor air cooled

Englisch

Installation conditions, cooling details

2.6

Surroundings:

The motor can be installed in roofed over rooms with dusty or damp ambient conditions and normal climatic

conditions. In general, the motor may not be brought into contact with aggressive, corrosive, abrasive or plas-

tic-dissolving solutions. Dust filters with micro-filter mats must be interposed where air containing dust parti-

cles are used as cooling air.

The warmed-up motor exhaust air

– even of adjacent units – must not be taken in again.

Consultation with the motor manufacturer is essential in the case of outside installation.

For ambient conditions refer to

chapter 2.4

and the technical documentation that comes with the product.

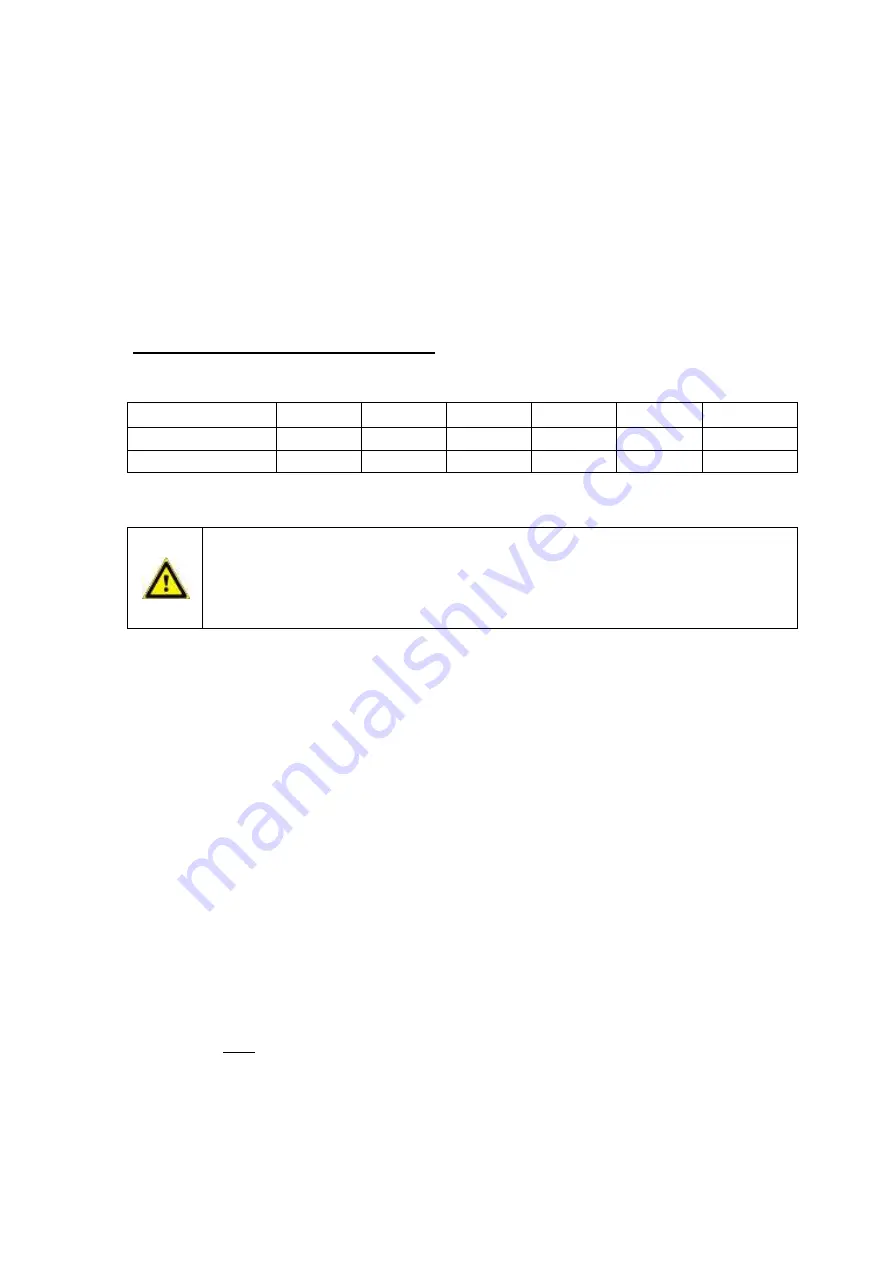

Information on required cooling quantities

The following approximate air quantities are required to cool the DA motors.

DA frame size

100

132

160

180

225

280

Air quantity in m³/min

2.5

5.8

9.5

16.5

23

35

Pressure level in Pa

180

360

630

850

950

1900

Balancing, vibrations

2.7

The shaft and bearing must not be exposed to knocks.

No axial forces are permitted when mounting or dismounting the output elements.

The generally required measures to prevent contact with the output elements must be observed.

If the motor is commissioned without the output element, the featherkey must be secured to

ensure that it is not thrown out.

Balancing:

In the standard version, the rotors are balanced dynamically with half the featherkey inserted.

(In accordance with DIN EN 60034-14 / ISO 1940)

NOTE:

The balancing method is marked on the shaft end face:

H = Balancing with half featherkey - standard version

F = Balancing with full featherkey - special version

Output elements:

When assembling the output element, make sure that the correct balancing method is used. The output ele-

ments must be balanced in accordance with ISO 1940.

Suitable devices should always be used to push on or pull off the output elements (e.g. coupler disk, gear

wheel or belt pulley).

•

Use tapped hole at end of shaft.

•

When pulling off, use spacer washer for mechanical protection of shaft.

•

If necessary, heat the output element

(max. permitted temperature at the shaft end 150°C).

CAUTION:

If the shaft does not have a featherkey, the output elements are fixed to the drive shaft using

appropri-

ate clamping bushes

.

•

In the case of shafts with a featherkey, make sure that the output elements are fitting

the shoulder of

the shaft

. Note: The chamfer or radius at the output element and the shaft radius at the shoulder have to

be harmonized.