TAM 00682

28

DSC 045-100

07 / 2012

Three-phase synchronous motor

English

9.6

Coolant consistency

The coolant must satisfy the following specifications:

Conditions Unit

Value

Maximum permissible systempressure

bar

6

Temperature of coolant- for motor

°C

10 to 25

pH value (at 20 °C)

---

6.5 to 9

Overall hardness

mmol / l

1.43 to 2.5

Chloride - Cl-

mg / l

< 200

Sulfate - SO

4

²-

mg / l

< 200

Oil

mg / l

< 1

Permissible particle size of solid foreign objects,

particles (e.g., sand)

mm <

0.1

Table 8: Coolant consistency

Clean water that is free of dirt and suspended matter must be used as a coolant.

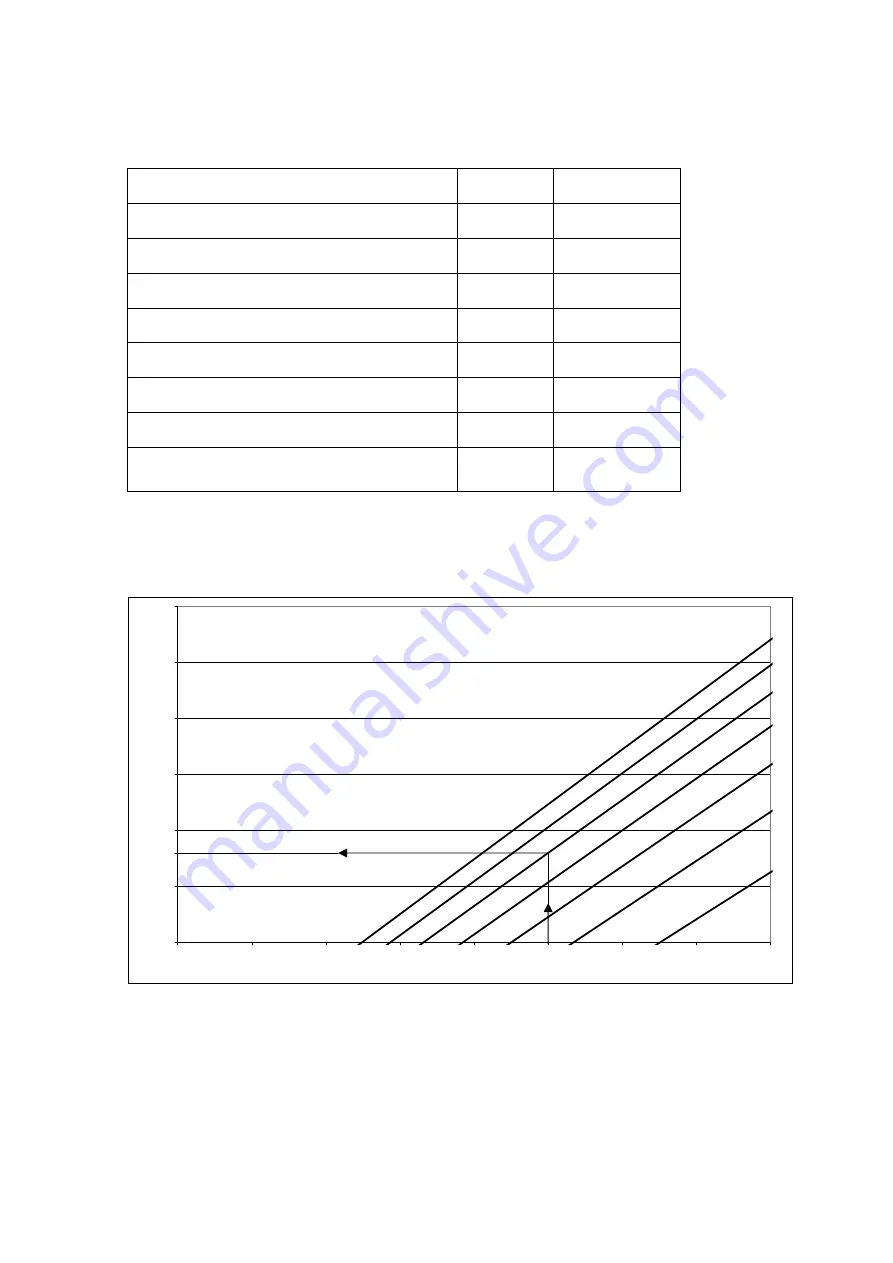

9.7

Min. coolant temperature against ambient temperature and humidity

25

%

rel

. h

um

idi

ty

35

%

rel

. h

um

idi

ty

45

%

rel

. h

um

idi

ty

55

%

re

l. h

um

idi

ty

65

%

rel

. h

um

idi

ty

75

%

re

l. h

um

idi

ty

85

%

re

l. h

um

idi

ty

10

15

20

25

30

35

40

0

5

10

15

20

25

30

35

40

ambient temperature (°C)

m

in. coo

lan

t t

em

p

er

at

ur

e (

°C

)

Figure 12: Determination of the coolant temperature

The allowed coolant temperature depends on relative humidity and ambient temperature. For

example with an ambient temperature of 25 °C and a relative humidity of 65 % the minimum

coolant temperature is 18 °C. Because these are limiting values on practical side a coolant

temperature greater than 18 °C should be used.

If this minimum coolant temperature will be under run the two- point controller of Baumüller drive

must be used to avoid condensation (see

figure 13

on next page).