TAM00721

16

DSD-028 / DSD-036 / DSD2-028 / DSD2-036

04/2013

Three-phase-synchronous motor

English

Have the following information ready:

•

Nameplate data

•

type and scope of the malfunction, situation on occurrence of the malfunction

•

application data (torque cycle, speed and forces over time; ambient conditions)

The following selection of possible causes can be helpful in the fault rectification process:

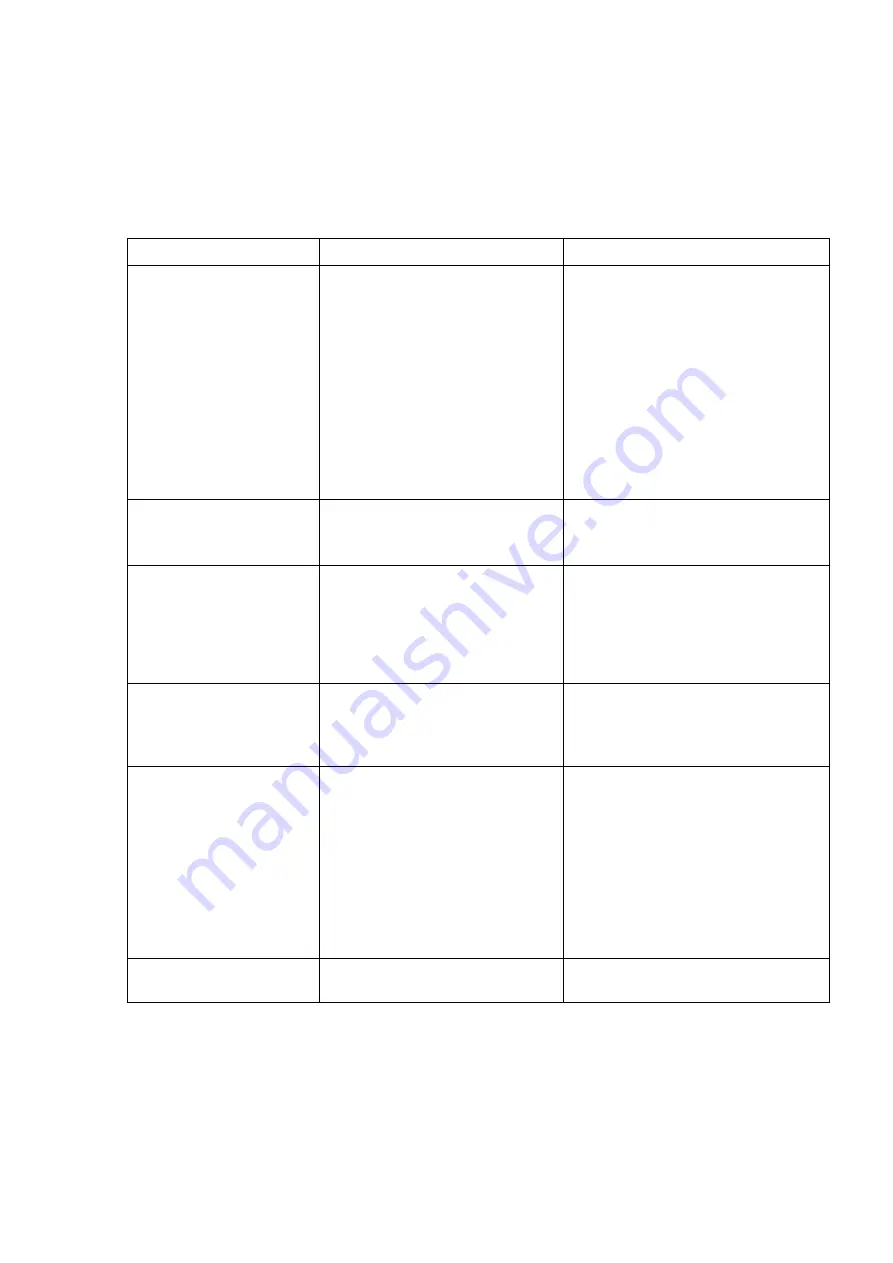

Malfunction

Cause

Remedy

Motor does not start

No controller enable

Controller fault, encoder fault

Brake does not release

Faulty brake

No power supply

Rotating field

Activate controller enable

Read out fault list on the converter or

controller; rectify faults

Check control, connections, and

power supply

Repairs carried out by manufacturer

Check connections and power supply

Check phase sequence. If

necessary, switch over the

connecting cables

Uneven running

Insufficient screening on

connecting cables

Controller parameters too high

Check screening connection and

grounding

Optimise controller parameters

Vibrations

Coupling element or driven

machine poorly balanced

Inadequate alignment of the drive

train

Fixing screws loose

Rebalance

Realign machine set

Check and tighten screwed

connections

Running noises

Foreign bodies in the motor

Bearing damage

Repairs carried out by motor

manufacturer

Repairs carried out by motor

manufacturer

Temperature rise in the

motor

Motor temperature

monitoring unit trips

Drive overload

Motor surface/airways dirty

as been installed in an area that

does not allow enough space

Brake not releasing fully – brake

dragging

Check motor load and compare with

nameplate

Clean motor surface/airways

Check motor has been installed in

acc. with Sections 2.6 and 3.2

Have repaired by motor manufacturer

Current consumption too

high, motor torque too low

Indexing angle incorrect

Check indexing angle and adjust if

necessary

Table 3: Malfunctions