TAM 00746

29

DSP1 045 - 100

11 / 2019

Three phase synchronous motor

English

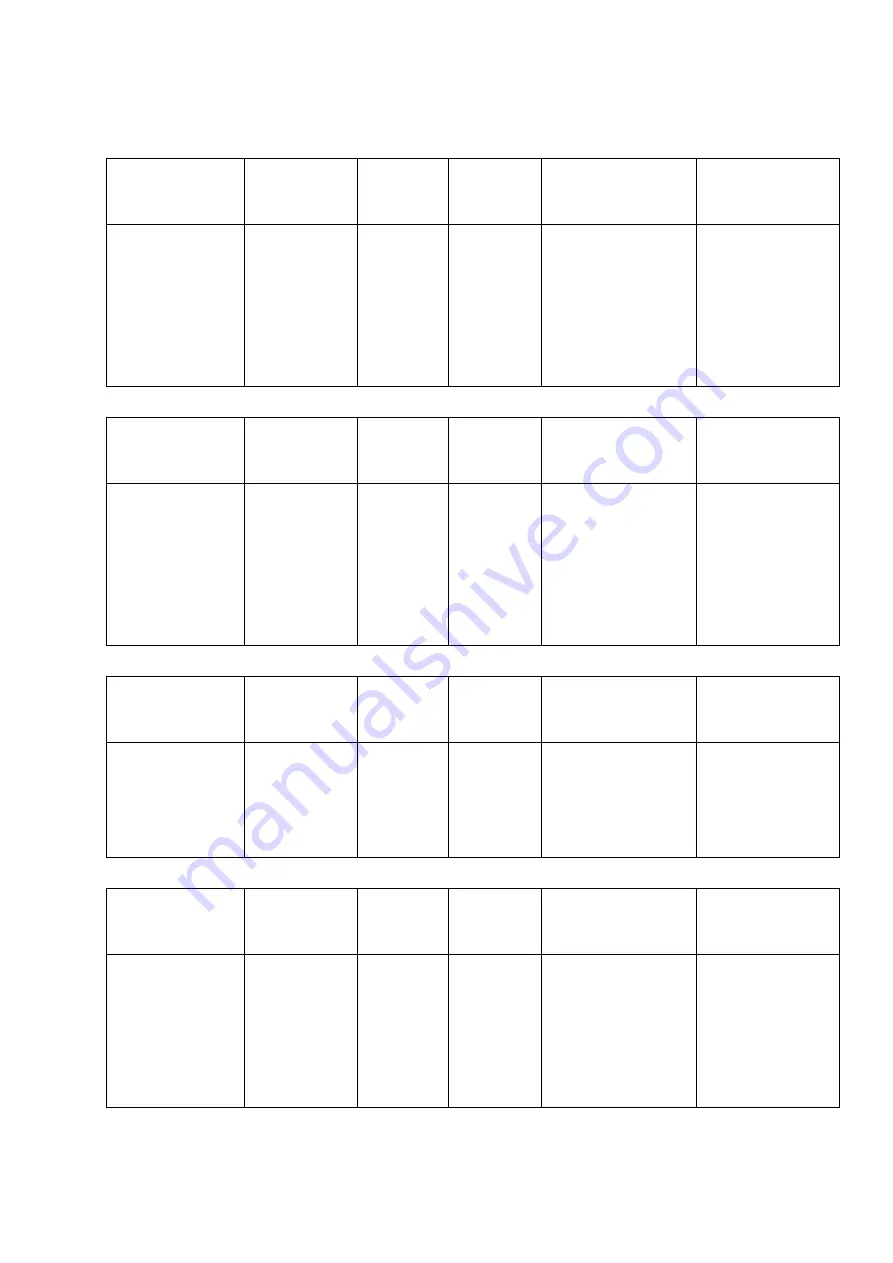

9.5 Information on the required coolant volume rate of flow

Motor type

Volume rate of

flow

[l/min]

Pressure

drop

15 % [bar]

Tempera-

ture in-

crease

[K]

Max. coolant pressure

[bar]

Coonnection (2x)

[mm]

DSP1-045KO64W

5

1,0

2

6

Quick coupling for

hose connection (Ø8

mm)

DSP1-045SO64W

5

1,1

2

6

Quick coupling for

hose connection (Ø8

mm)

DSP1-045MO64W

5

1,2

2

6

Quick coupling for

hose connection (Ø8

mm)

Motor type

Volume rate of

flow

[l/min]

Pressure

drop

15 % [bar]

Tempera-

ture in-

crease

[K]

Max. coolant pressure

[bar]

Coonnection (2x)

[mm]

DSP1-056KO64W

5

0,5

2

6

Quick coupling for

hose connection (Ø8

mm)

DSP1-056SO64W

5

0,5

2

6

Quick coupling for

hose connection (Ø8

mm)

DSP1-056MO64W

5

0,6

2

6

Quick coupling for

hose connection (Ø8

mm)

Motor type

Volume rate of

flow

[l/min]

Pressure

drop

15 % [bar]

Tempera-

ture in-

crease

[K]

Max. coolant pressure

[bar]

Coonnection (2x)

[mm]

DSP1-071KO64W

5

0,33

3

6

Edelstahlrohr Ø8x1

DSP1-071SO64W

5

0,4

5

6

Edelstahlrohr Ø8x1

DSP1-071MO64W

5

0,5

6

6

Edelstahlrohr Ø8x1

Motor type

Volume rate of

flow

[l/min]

Pressure

drop

15 % [bar]

Tempera-

ture in-

crease

[K]

Max. coolant pressure

[bar]

Coonnection (2x)

[mm]

DSP1-100KO64W

5

0,34

3

6

Stainless steel pipe

Ø8x1

DSP1-100SO64W

5

0,4

5

6

Stainless steel pipe

Ø8x1

DSP1-100MO64W

5

0,46

7

6

Stainless steel pipe

Ø8x1

DSP1-100LO64W

5

0,52

9

6

Stainless steel pipe

Ø8x1

Table 7: Coolant volume rate of flow