©

Baxi Heating U.K. Limited 2006.

5119074/01

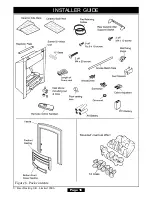

INSTALLER GUIDE

We trust that this guide gives sufficient details to enable this appliance to be installed

and maintained satisfactorily. However, if further information is required,our

Baxi Fires Division Technical Helpline

will be pleased to help.

Telephone

08706 061 065

(National call rates apply in the United Kingdom)

In the Republic of Ireland telephone

0044 8706 061 065.

INSTALLER: Please leave this guide with the

owner

THIS APPLIANCE IS FOR USE WITH NATURAL GAS (G20).

WHEN CONVERTED USING CONVERSION KIT NO. 0595211 THIS

APPLIANCE IS FOR USE WITH PROPANE GAS (G31).

THIS APPLIANCE IS SUITABLE ONLY FOR INSTALLATION IN THE UNITED

KINGDOM (GB) AND THE REPUBLIC OF IRELAND (IE).

Model 742

REMOTE CONTROL

INSET LIVE FUEL EFFECT GAS FIRE

Fitted with the

Knightsbridge

fascia.

(GC No. 32-264-21)