6.1.4

Installations using a metal flue box

The whole of the top surface of the metal flue box must be covered with a 100mm layer

of mineral wool or equivalent insulation (See figure 2).

6.2 Fireplace flue pull.

Close all doors and windows in the room in which the appliance is to be installed. After

confirming with a match that smoke is drawn into the flue, light a 13 gram smoke pellet

and check that there is a definite flow through the flue. Verify outside that the smoke

exits from one terminal only and that the termination is suitable. Observe where

possible, upstairs rooms and loft spaces for signs of escaping smoke indicating a

defective flue. If there is not a definite flow warm the flue for a few minutes and repeat

the smoke pellet test. If there is still no definite flow the flue may need remedial work –

Do not fit the appliance until there is a definite flow through the flue.

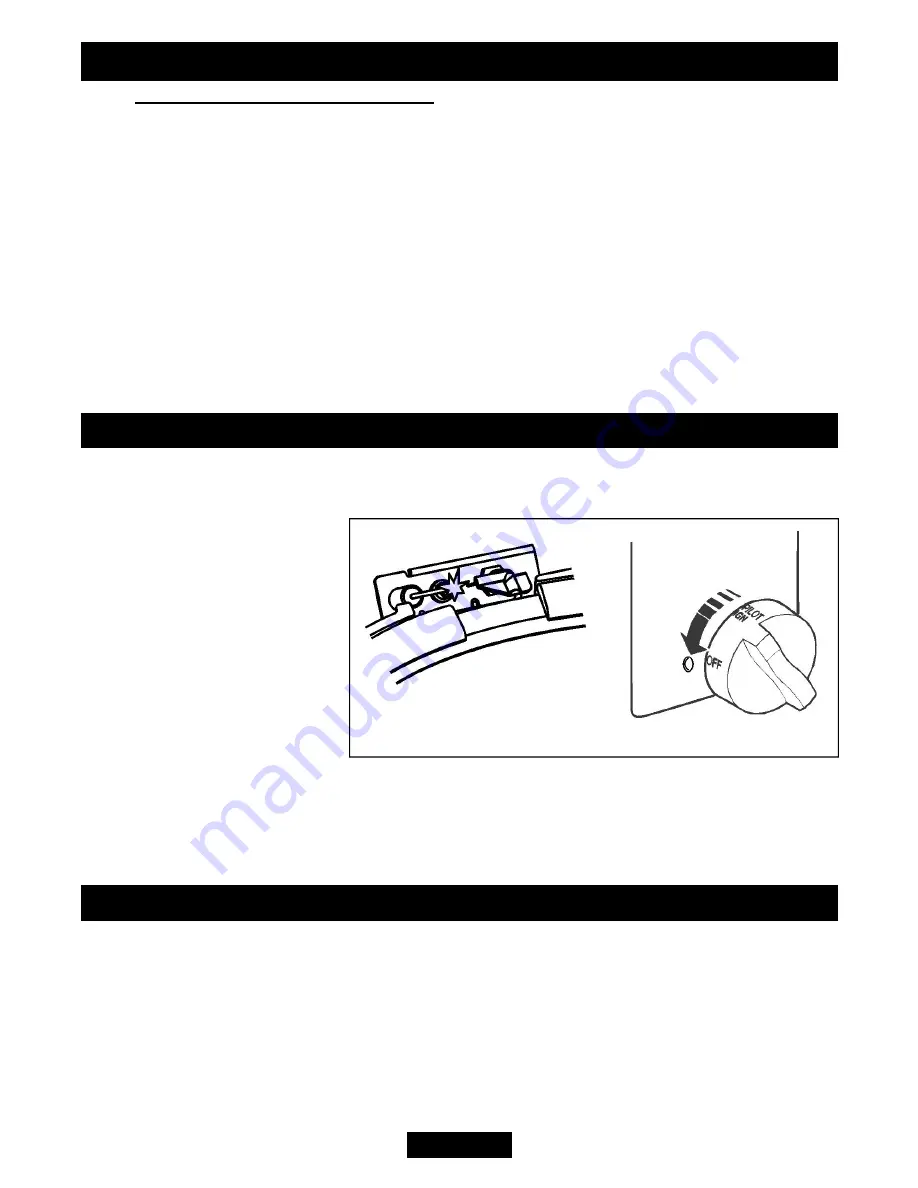

7. IGNITION CHECK

Before attempting to install, it is worth checking that the ignition system performs

satisfactorily.

Set the control knob to the off

position. Depress the control

knob and rotate it

anticlockwise to the pilot

ignition position. A 'click' will

be heard as the integral piezo

operates. A spark should be

seen between the electrode and

pilot tip. If there is no spark

check the following: -

!

Ensure that the electrode lead is connected to the terminal at the base of the

electrode.

!

If the above is correct, check for damage to the electrode lead.

8. GAS SUPPLY CONNECTION

A nut and olive are provided for an 8mm pipe inlet connection to the ‘T’ connector at

the bottom front of the appliance. The ‘T’ connector can be rotated to allow a

connection from any rear-concealed connection. The ‘T’ connector includes a valve for

isolating the gas supply and a pressure test point.

The supply pipe must be rigid material. Flexible pipe must not be used.

Concealed supply pipe connection.

If a concealed connection from inside the fireplace is required then

,

before the

Page 14

INSTALLER GUIDE

Figure 8. Ignition operation