14.

Feed the free length of the cables into the gap between the inner and outer back

panels so that they are available to allow easy removal and refitting of the appliance

during subsequent service calls.

Do not cut off the free lengths of cable.

On precast

flue installations feed the cables into the small holes at the base of the side panels.

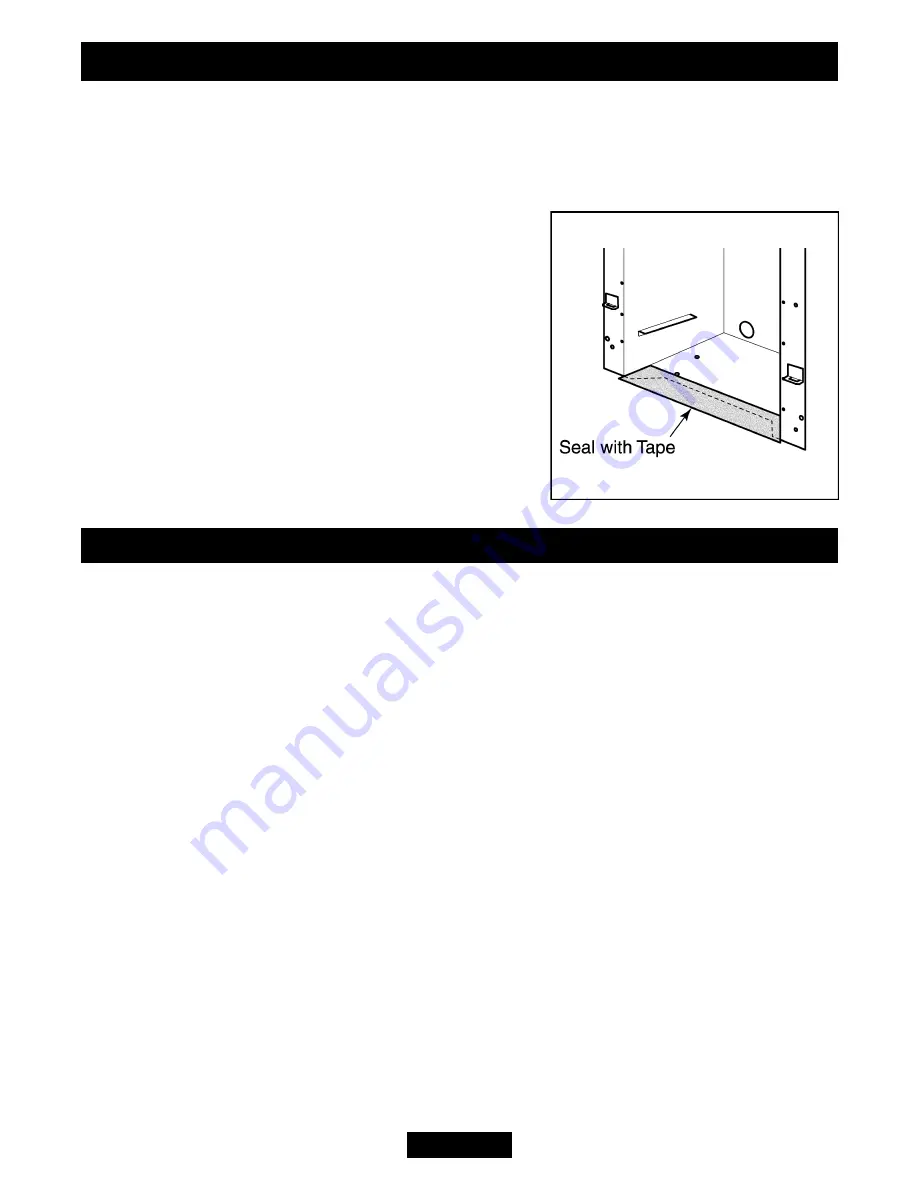

10.2 Sealing floor front - all installations.

Using the floor sealing tape supplied, seal the bottom

of the hotbox to the fireplace and hearth floor (See

figure 22).

Make sure that the whole length of the front edge

of the hotbox is fully sealed.

11. BURNER & SUPPLY PIPE INSTALLATION

11.1 Fitting the burner.

1.

Place the burner assembly into the hotbox and secure using the two screws removed

previously.

2.

Supplied with the fire is an eliptical burner bezel. Place this within the edge of the

burner so that it covers the screws that secure the burner top surface. The gap in the

elipse should be positioned so that the pilot flame passes

through

it.

11.2 Supply pipe installation.

A nut and olive is provided for an 8mm-pipe inlet connection directly to the gas control.

The isolating ‘T’ connector can be rotated to allow a connection from any direction. The

‘T’ connector includes a valve for isolating the gas supply.

The supply pipe must be rigid material. Flexible pipe must not be used. Connect the

supply line to the appliance.

Turn on the gas supply and pressure check the installation pipework for gas soundness.

In the United Kingdom (GB) check in accordance with the current edition of BS 6891.

In the Republic of Ireland check in accordance with the current edition of IS 813

“Domestic Gas Installations”

11.3 Preliminary burner checks.

Some burner operations can be checked at this stage. Checking now will mean that less

disassembly will be required if any problems are found.

A full check should still be

Page 20

INSTALLER GUIDE

Figure 22. Floor sealing