INSTALLING THE FIRE

Your

CORGI

qualified gas engineer should install

the fire in accordance with the following

regulations and standards:-

The Gas Safety (Installation and Use) Regulations

1998 (as amended).

The Building Regulations for England and Wales

2000 ref; Approved Document J 2002 edition

(issued by the DTLR).

The Building Standards (Scotland) (Consolidation)

Regulations.

BS5440 parts 1 and 2 1990, BS5871 And these

Installation Instructions.

Warning: Failure to comply with the

regulations, requirements, or these instructions

will invalidate the guarantee and could have

hazardous consequences.

Please note that in tight recesses the gas supply

point may be inaccessible. Therefore it may be

necessary to connect the pipe for the gas supply to

the fire before installing the fire into its recess.

FITTING THE FEET

Care should be taken when fitting the feet not to

damage the painted surfaces of the fire.

• The feet (4 off) are positioned in each corner of

the fire base using the washers and screws

provided.

•

Tools required

: A no. 2 pozidrive screwdriver.

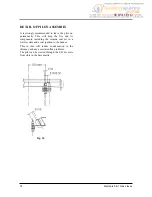

FLUE SYSTEM

The stove must be connected to a suitable and

efficient flue that provides a good updraught to

safely take the products of combustion (fumes)

from the stove outlet to the outside air. To ensure a

good updraught it is important that the flue gases

are kept warm and that the flue size suits the stove.

The termination of the outlet at the top of the flue

also needs to comply with the Building

Regulations. The minimum effective height of the

chimney must be at least 3 metres and when warm

the flue draught should be between 0.05 and 6mb

(0.5mm to 6mm water gauge).

The Memphis 3 requires a minimum flue size of

100mm (4 inches) and the Memphis 4 requires a

minimum flue size of 125mm (5 inches). If the

stove is being connected to a chimney with an inter-

nal flue size greater than 225mm (9 inches) diame-

ter or 200 x 200mm square, a 125mm (5 inches)

diameter stainless steel flexible flue liner comply-

ing with BS 715 should be installed in the flue.

If a new chimney is being provided it should fully

comply with the relevant Building Regulation

Requirements and BS 5440: Part 1. Suitable types

of chimney include the following.

• Masonry chimney built with clay or concrete lin-

ers, or a chimney block system meeting Building

Regulations.

• Precast concrete gas flue block complying with

BS 1289: Part 1

Factory made metal chimney complying with BS

715 (often called "Twin wall Class 2 chimney") or

Factory made metal insulated chimney comply-

ing with BS 4543: Part 2 (often called "Class 1 pre-

fabricated metal chimney"). To ensure the flue

gases are kept warm an insulated chimney system

should be used if the chimney is positioned outside

the building.

The flue must be terminated with a suitable

chimney pot or cowl and the chimney or flue shall

be swept prior to installation unless the chimney is

clean and unobstructed.

The flue and chimney installation must be

carefully checked by a competent person before

fitting the stove to ensure it is suitable and will

work safely. The flue must also pass a Flue flow

test (smoke test) to BS 5440: Part 1.

For advice on flues and chimneys contact;

NACE (National Association of Chimney

Engineer): telephone 0800 0924019

www.nace.org.uk

or

NACS (National Association of Chimney

Sweeps): telephone 01785 811732

Memphis 5 & 7 Gas stoves

11

INSTALLATION