28

19. Positioning of the ignition

and flame sensing electrode

Figure 16

010905_0200

To measure combustion performance and hygiene levels of combustion products, the forced draught

boiler models are equipped with two test points on the tapered coupling specifically designed for this

purpose.

One of the two test points is connected to the exhaust flue duct to allow measurements of the combustion

products hygienic standards and combustion efficiency.

The second test point is connected to the comburant air inlet duct to check possible combustion

products circulation in case of coaxial ducts.

The exhaust flue duct test point allows measurements of the following:

• combustion products temperature;

• concentration of oxygen (O

2

) or, alternatively, of carbon dioxyde (CO

2

);

• concentration of carbon monoxyde (CO).

The comburant air temperature must be measured at the test point connected to the air inlet duct.

20. Check of combustion

parameters

Figure 17

020429_0300

flue gas

combustion air

gasket

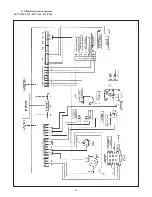

To facilitate measurement of the combustion efficiency and improve the cleanliness of the production

products, the flue-sweeper function can be activated by proceeding as described below:

1) press the (2-3) together until the pointer “ ” appears on the display alongside the symbol

(about 3 seconds but no more than 6 seconds). In these conditions, the boiler operates at the

maximum heat output set for central heating.

2) press either of the buttons to exit the function

21. Activating the flue-sweeper

function