16

C607215 - GB

INSTRUCTIONS FOR FITTERS

15. CONTENTS OF PACK

• template

• gas tap (1)

• water supply tap (2)

• gaskets

• telescopic joints

• 8 mm rawlplugs and supports

Figure 6

0702_1202 / C

G_1892

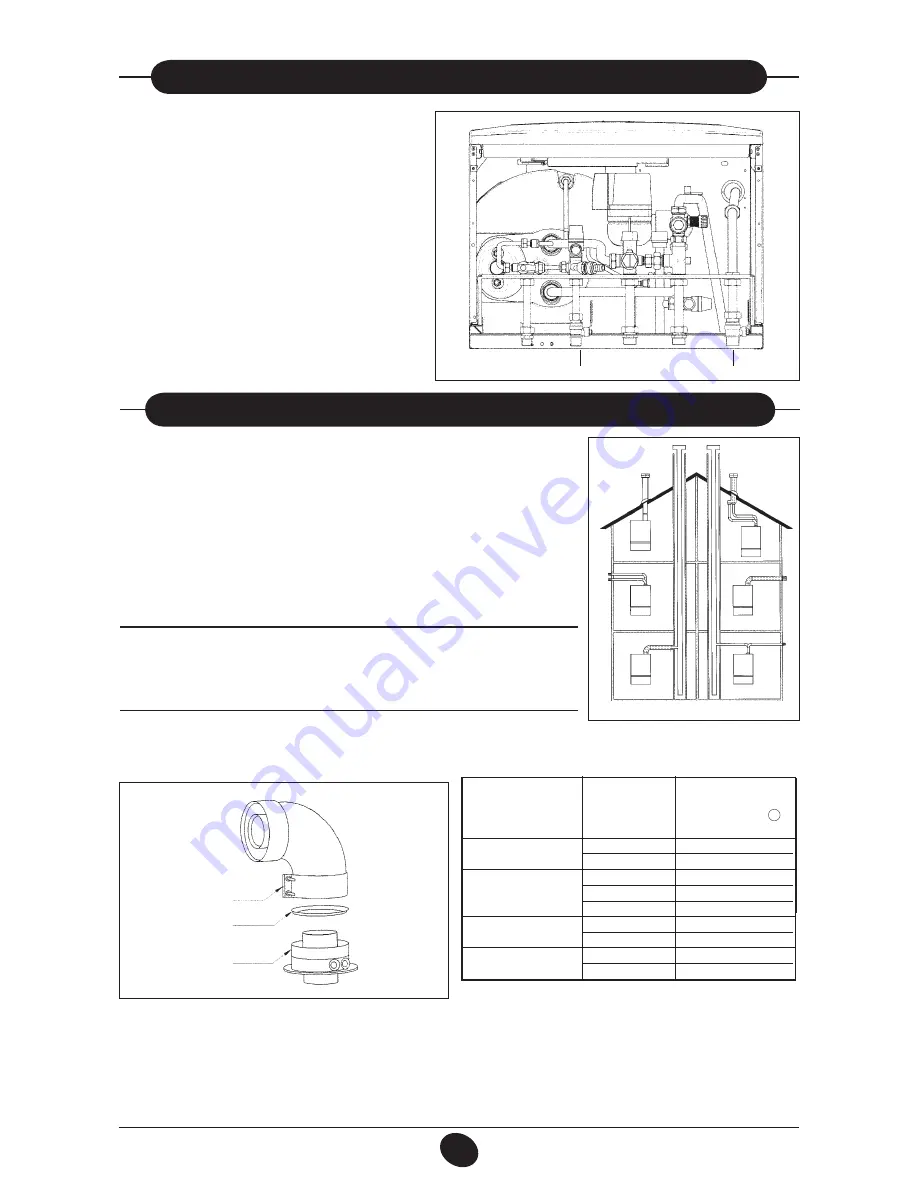

16. INSTALLING THE FLUE AND AIR DUCTS

The boiler is easy and flexible to install thanks to the extensive range of available accessories,

as described below. The boiler has been designed for connection to a vertical or horizontal

coaxial flue-air duct. A splitting kit is also available if separate ducts are required.

Only accessories supplied by the manufacturer must be used for installation!

… Coaxial flue-air duct (concentric)

This type of duct is used to discharge exhaust fumes and draw combustion air both outside

the building and if a LAS flue is fitted.

The 90° coaxial bend allows the boiler to be connected to a flue-air duct in any direction

as it can be rotated by 360°. It can also be used as a supplementary bend combined with a

coaxial duct or a 45° bend.

WARNING

To optimise operating safety, make sure the flue ducts are firmly fixed to

the wall with suitable brackets.

911231_5500

Figure 7

2

1

MAX.

INLET

LENGTH

DIAPHRAGM A

(m)

(mm)

0 ÷ 2,5

73

2,5 ÷ 5

NO

0 ÷ 0,5

73

0,5 ÷ 2

80

2 ÷ 4

NO

0 ÷ 1

76

1 ÷ 4

NO

0 ÷ 1

80

1 ÷ 3

NO

NUVOLA 3 240 Fi

NUVOLA 3 280 Fi

Figure 8

BOILER MODEL

If fumes are discharged outside the building, the flue-air duct must protrude at least 18 mm from the wall to allow an aluminium we-

athering surround to be fitted and sealed to avoid water infiltrations. Make sure there is a minimum upward slope towards the outside

of 1 cm per metre of duct.

a 90° bend reduces total duct length by 1 metre.

a 45° bend reduces total duct length by 0.5 metres.

0712_0801

Connector

Concentric ad

A

NUVOLA 3 320 Fi

NUVOLA 3 140 Fi