18

C607215 - GB

INSTRUCTIONS FOR FITTERS

For detailed installation instructions, consult the technical data provided with the accessories.

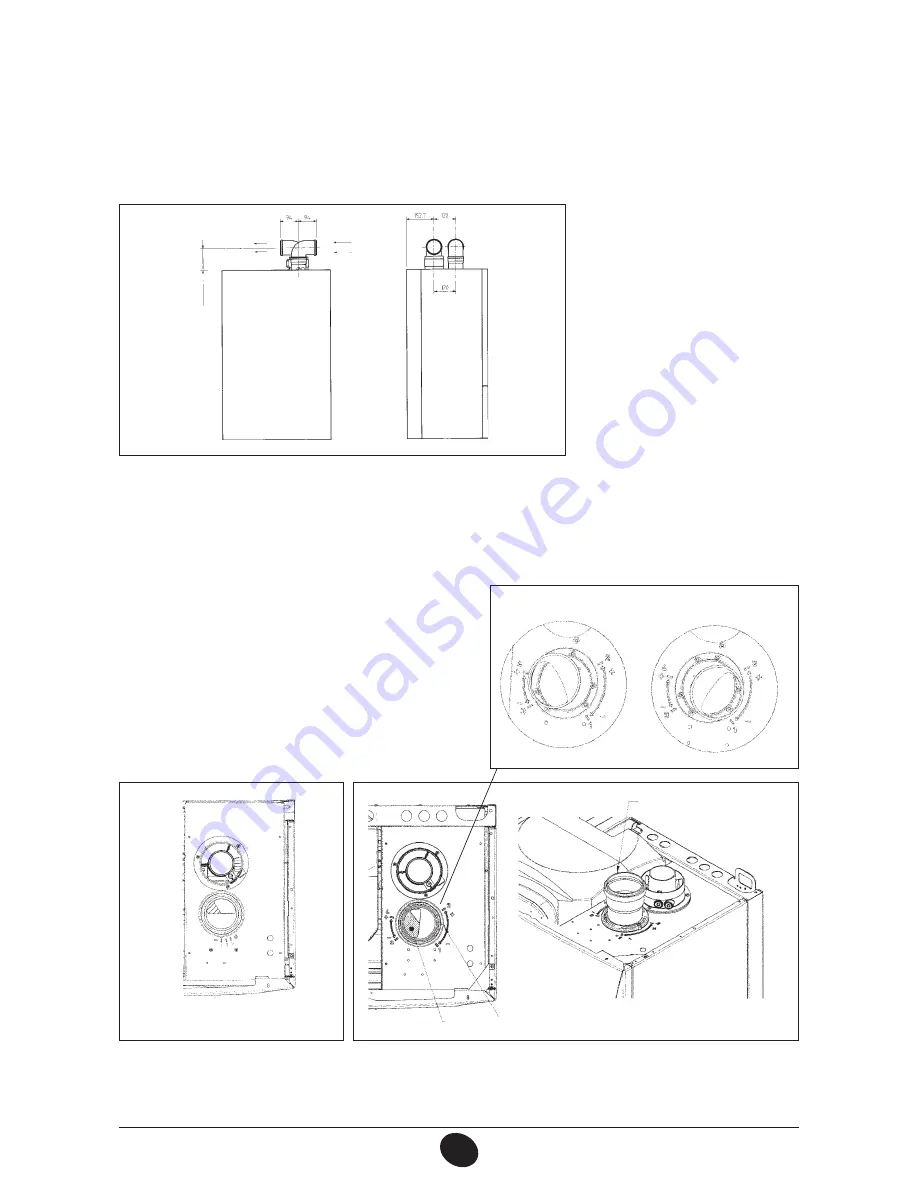

… separate flue and air ducts

This type of installation makes it possible to discharge exhaust fumes both outside the building and into single flue ducts. Comburent

air can be drawn in at a different location from that of the flue terminal. The splitting kit comprises a flue duct adaptor (100/80) and an

air duct adaptor. For the air duct adaptor, fit the screws and seals previously removed from the cap.

The diaphragm in the boiler must be removed in the event of installation with these types of ducts.

• A 90° bend reduces total duct length by 0.5 metres.

• A 45° bend reduces total duct length by 0.25 metres.

Figure 10

Adjusting the air regulator for separate flues

This regulator must be adjusted to optimise combustion efficiency and parameters. After turning the air intake connecter, which can be

mounted both to the right and the left of the exhaust flue duct, suitably adjust the excess air according to the total length of the combu-

stion exhaust and inlet flue ducts.

0802_2504 / (C

G_2022)

0812_1905

0604_2001

NUVOLA 140 Fi

NOTE:

The first 90° bend is not included

when calculating the maximum available

length.

The 90° bend allows the boiler to be con-

nected to a flue-air duct in any direction as

it can be rotated by 360°. It can also be used

as a supplementary bend combined with a

duct or a 45° bend.

Model 240-280

Model 320

Turn this regulator clockwise to decrease the excess of comburent air and

vice versa to increase it.

To fine tune, use a combustion product analyser to measure the amount

of CO2 in the fumes at maximum heat capacity, and, if a lower value is

measured, gradually adjust the air regulator until the amount of CO2 in-

dicated in the following table is measured. To mount this device correctly,

consult the relative instructions.

Index

Opening

Intake coupling

Figure 9

0805_2101 / CG_2023

135 m

in

im

um