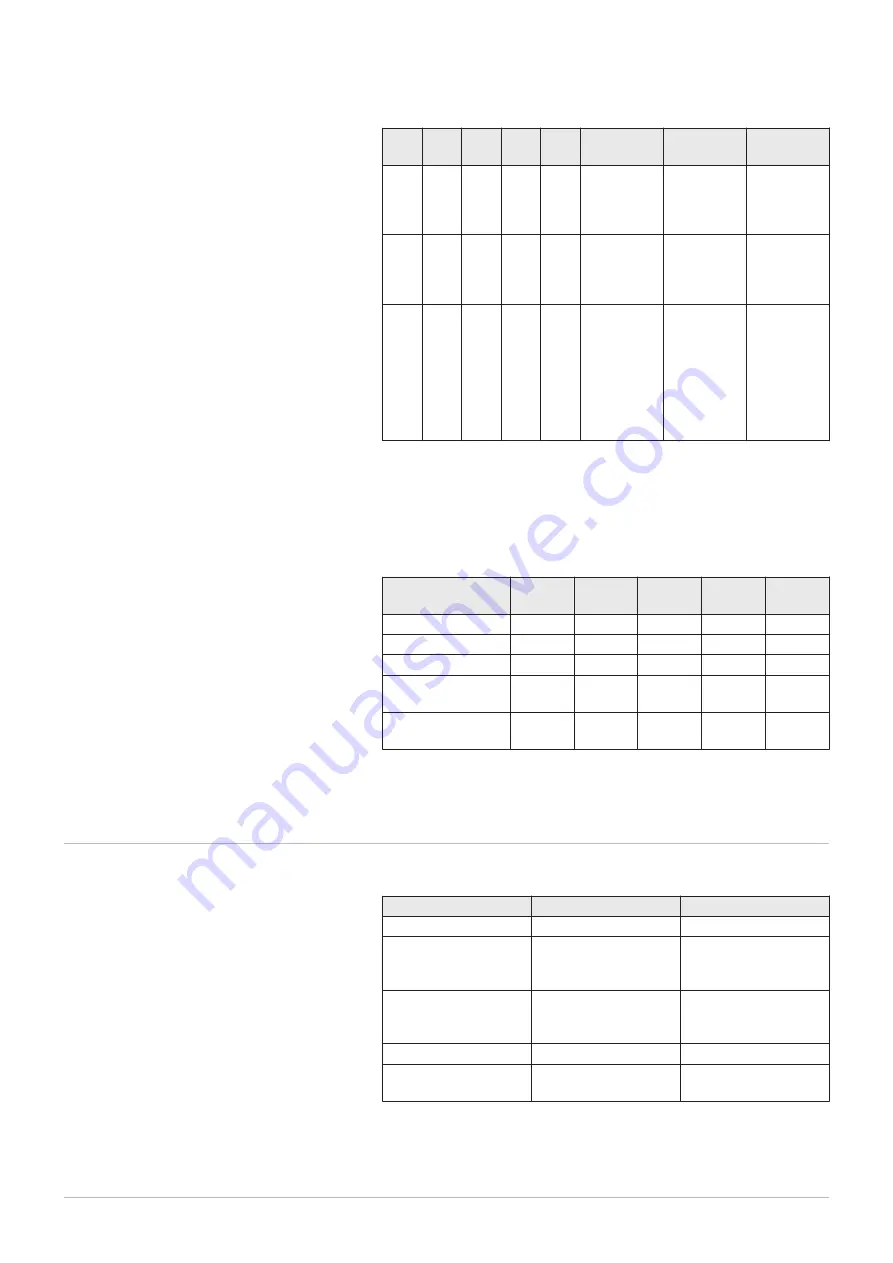

Tab.11 Sequence of error alarms

LED

1

LED

2

LED

3

LED

4

LED

5

Indications Pump ope

ration

Action

x

x

Rotor blo

cked

Attempt res

tart every

1.33 se

conds

Wait and

unblock the

shaft

x

x

Voltage

supplied too

low

Warning

only, pumps

continues to

run

Check the

voltage sup

plied

x

x

Electrical

fault

The pump

has stopped

running be

cause the

voltage sup

plied is low,

or there is a

serious fault

Check the

voltage sup

plied. Re

place the

pump

When there are no active alarms, the operation panel returns to

operational mode.

It works with an external solar profile PWM C or in internal control with

constant curve.

Tab.12 Operating status

LED 1

(green)

LED 2

(green)

LED 3

(yellow)

LED 4

(yellow)

LED 5

(yellow)

CC1

x

CC2

x

x

CC3

x

x

x

PWM C shutdown

signal

x *

x

x

x

PWM C start-up

signal

x**

x

x

x

(*) 1 flash per second

(**) 2 flashes per second

8.3

Pump technical data

Tab.13 Technical data

UPM3 15-75

UPM3 15-145

Pressure system

Max. 1.0 MPa (10 bar) Max. 1.0 MPa (10 bar)

Minimum input pressu

re

0.05 MPa (0.50 bar) at

95 °C of fluid tempera

ture

0.05 MPa (0.50 bar) at

95 °C of fluid tempera

ture

Fluid temperature

2-110 °C (TF110) Max.

130 °C (60 °C ambient

temperature)

2-110 °C (TF110) Max.

130 °C (60 °C ambient

temperature)

IP class

IPX4D

IPX4D

Motor protection

No external protection

necessary

No external protection

necessary

8 Solar pump

7729335 - 04 - 12052021

Solar hydraulic unit

29