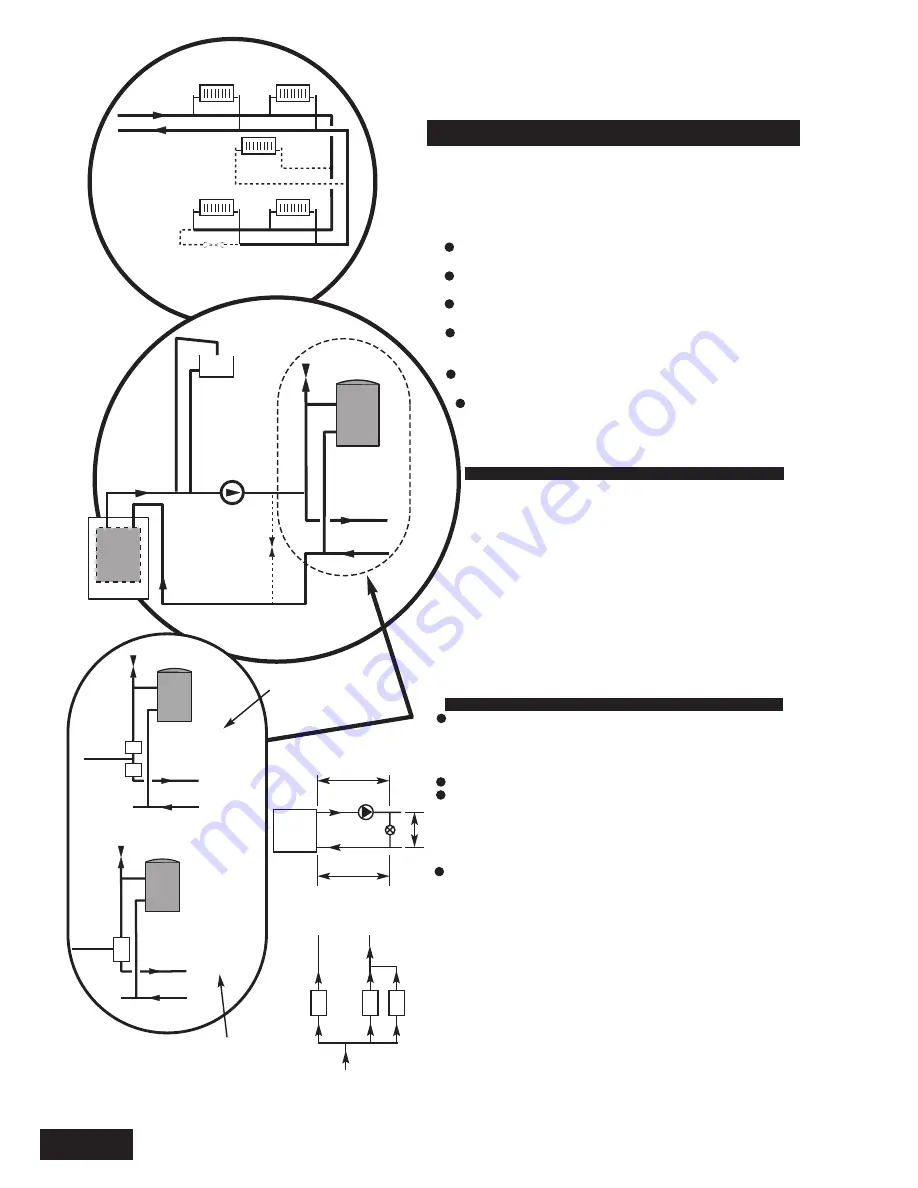

This system is unlikely to

require a By-pass unless all

radiators are thermostatically

controlled

Water Circulating Systems

The appliance is suitable for use with fully pumped

open vented systems (small bore and micro-bore),

gravity domestic hot water with pumped central heating

systems and sealed systems.

The following conditions should be observed on all

systems:

The static head must not exceed 30m (100ft) of

water.

The boiler must only be used with an indirect

cylinder.

Drain points should be fitted to the lowest points in

the system.

All electrical wiring, gas and water pipes must be

installed in a way which would not restrict the servicing

of the boiler.

Position isolating valves as close to circulating pump

as practicable.

For fuel economy and best boiler performance, the

system should be designed so that gravity circulation

does not take place in the heating system when the

pump is not running.

Treatment of Water Circulating Systems

For optimum performance after installation, this boiler and its

associated central heating system must be flushed in

accordance with the guidelines given in BS7593:1992

“Treatment of water in domestic hot water central heating

systems”.

This must involve the use of a proprietry cleanser, such as

BetzDearborn’s Sentinel X300 or X400, or Fernox’s Superfloc. Full

instructions are supplied with the products but for immediate

information please contact BetzDearborn on 0151 420 9563, or

Fernox on 01799 550811.

For long term protection against corrosion and scale, after flushing it

is recommended that an inhibitor such as BetzDearborn’s Sentinel

X100, or Fernox’s MB-1 or Copal is dosed in accordance with the

guidelines given in BS7593:1992.

Failure to flush and add inhibitor to the system may

invalidate the appliance warranty.

BYPASS REQUIREMENTS

The boiler is fitted with a pump overrun device which allows the

removal of residual heat from the boiler. NOTE: The pump overrun

will operate for approximately 3 minutes. The system design must

therefore always provide an open circuit for water to circulate

between the boiler flow and return.

If a system has an open circuit a bypass is not required.

A system using a 3 port diverter valve does not normally require a

bypass and therefore this system is recommended. The exception to

this is where all radiators in the system are fitted with thermostatic

valves, in which case a bypass would be required. However, if one

radiator in such a system was fitted with 2 lockshield valves a bypass

would not be required.

A system controlled by non-electrical valves e.g. mechanical

thermostatic control valves both on the radiators and the hot water

circuit and systems using twin zone valves (e.g. Honeywell 'S' Plan)

will require a bypass.

The bypass circuit can be:-

A) A minimum of 9 metres of 22mm pipe (measured between the

boiler flow and return connections). It should be fitted with a

lockshield valve opened at least 1 full turn to give a minimum flow rate

of 8 litres/min (1.8 gal/min).

B) A radiator fitted with lockshield valves. The radiator output should

be a minimum of 800 watts (2,700 Btu/h). Typically a convector type

radiator with an area of 3750 cm

2

(4ft

2

) is adequate.

C) By including an automatic bypass valve in the system (see

diagram).

D) Any circuit that provides the same operating conditions as option A

or option B.

Radiator Circuit

Examples of

Open Circuits

By-pass

Loops

SYSTEM DETAILS

(and By-pass Requirements)

Air Vent

Boiler

Pump

Radiator

Circuit

Fully Pumped System

Optional

Bypass

8

A By-pass is

required with

this system

Air

Vent

Radiator

Circuit

Twin Zone

Valve System

Air

Vent

Radiator

Circuit

3 Port Diverter

Valve System

Typical Systems Arrangement

B

F

R

B

C

C

A

A

Flow from boiler

Boiler

Pump

Valve

A = D. H. W. Zone valve

B = C. H. Zone valve

C = Automatic Bypass valve

Bypass length = A + B + C

Bypass Incorporating

Automatic Valve

Bypass Length