30

EN

CHECKLIST FOR INSTALLERS

Once the equipment is installed, installers should check that:

1. Primary system insulated pipes must always be mounted upstream. Small sections

can be horizontal but never downstream. This allows the air bubbles to rise to the

tank, thus preventing them from obstructing recirculation.

2. Make sure all bolts and nuts in the bracket are securely tightened.

3. Make sure there are no water leaks in the primary circuit.

4. Before operating the system, make sure that all valves are working properly and

that the system is completely filled with water and/or antifreeze fluid.

5. Make sure that the primary system works properly. This can be checked by touching

the intake pipe (upper part of the collector) and the return pipe to the reservoir

tank (bottom part of the collector). The intake pipe should be hot and the return

temperature should be significantly lower.

MAINTENANCE

1. System maintenance must be performed by a specialised technician.

2. Collectors:

•

Check for excessive dust on collectors at least once a year. They can be cleaned

with water, but collectors must be cooled to prevent the glass from breaking.

3. Reservoir tank:

•

Check the magnesium anode once a year and replace it if required.

•

Clean the reservoir tank when checking the condition of the anode.

4. Bracket:

•

The bracket must be checked for corrosion and decay every year.

•

Nuts must be tightened.

5. Installation:

• Check for leaks every year. Refill the system with water and glycol to prevent

freezing.

•

Check that safety valves work properly once a year, and, if needed, they should

be changed.

• Check that the pH of the fluid in the primary circuit is not under 7.

•

Check for leaks.

•

Perform an annual check to ensure that the water quality meets the requirements

of the Langelier index.

WARNINGS FOR USERS

•

Your solar system has two circuits. The primary circuit recirculates from the

collectors to the heat exchanger inside the reservoir tank, thus the solar radiation

heat is transferred to the reservoir tank.

•

Hot water temperature depends on the day’s solar radiation, season, ambient

temperature, inlet cold water temperature, time at which the hot water is used

and the amount of water used.

•

If you need hot water in the morning, avoid excessive consumption the previous

evening.

•

To avoid system freeze issues in very cold nights, it is advisable to leave a faucet

slightly open (dripping).

• In case of failure or malfunction, please, call the installer or qualified technical

service.

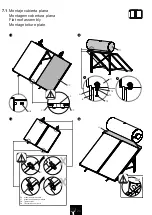

DISASSEMBLY:

1.

Empty solar fluid (water + glycol) in the primary circuit by loosening the nut

connecting the pipe to the bottom part of the collectors.

2. Close the water inlet and proceed to drain the ACS circuit.

3.

Make sure the liquid inside is not hot to prevent burns. The fluid inside is a mixture

of glycol and water; please, recycle or safely dispose of it and do not throw it

down the drain.

4. Disassemble the pipes.

5. Disassemble the reservoir tank.

6.

Disassemble solar collector(s).

7. Disassemble bracket.

RECYCLING:

Most of the thermosiphon system components are recyclable. The equipment can

be disassembled and its components can be sorted to be recycled.

NOTE:

Features and specifications subject to change without notice.

A heating resistance (optional) cannot be incorporated in the reservoir tank.

WARNINGS FOR INSTALLERS

•

Equipment must be kept at minimum recommended 0.5 m distance from su-

rrounding walls so that solar collectors are never in the shade and can be easily

maintained.

Drain lines should be led to sinks.

•

In the event that steel materials, stainless steel, etc. in addition to copper are

used for the installation avoid contact between them to prevent galvanic couples.

•

Particularly, in closed-circuit installations, in which solar liquid is a mixture of water

and glycol, the use of galvanized iron, aluminium and its alloys must be avoided.

•

Dielectric sleeves should be placed between the inlet and the outlet of the sanitary

water and the tank connections.

•

Pipes must be insulated in compliance with current regulations. Pipes connecting

the thermosyphon equipment come isolated and weather protected.

•

Any drain system to be placed in the hydraulic circuit must be isolated.

•

Special care must be taken with the pipes passing from the inside to the outside of

the building to prevent dampness.

•

Collectors should be protected from sunlight once the packaging is removed until

the installation is filled up.

•

In the case of lack of demand, or when long periods without removal of ACS are

expected, protect the system with thermal blankets or drain the system.

•

The cold water tap must always remain open.

•

Do not start the system in temperatures below zero.

INSTALLATION AND FILLING UP

•

Connect the lightning protection system.

• A mixing valve must be fit to the hot water outlet to prevent burns, because the

reservoir tank can reach temperatures above 60 °C.

If the inlet pressure exceeds 400 kPa (4 bar), a pressure reducer must be

installed to protect the entire system.

•

The following precautions must be taken when installing the safety valve:

•

Connect the secondary circuit to the network through the cold water inlet

(safety valve H6)

•

Do not install any shut-off valve between the safety valve and the reservoir tank.

•

Install the valve vertically to prevent dust and impurities from accumulating in

the drain inlet.

•

The safety valve must be led to the sink avoiding horizontal sections where

water can collect, preventing water from freezing. Piping should be installed

inside of the building as far as possible to prevent water from freezing.

•

Piping should be installed so that the steam or heat transfer medium coming

out the safety valve does not pose any risk to persons, materials or the envi-

ronment.

• The safety valve set to 800 kPa (8 bar), supplied with the cold water inlet pipe,

must be installed (secondary circuit). Do not install any shut-off valve between

the safety valve and the reservoir tank.

The secondary circuit (EHW) must be filled first.

•

Fill the ACS tank with water. Leave and open outlet to purge air.

• Fill by gravity the primary circuit through the 1/2” orifice located at the top of the

tank and mount the safety valve. The primary circuit contains glycol to prevent

possible freezing. Keep this in mind and do not refill the system with water only or

the system may freeze. The water and glycol must be mixed before adding to the

circuit.

If the ACS tank must be emptied, the primary circuit must be emptied first.

•

Purge all air from the installation.

HEAT TRANSFER FLUID

solar liquid can be used for filling the solar installation, with the appropiate

concentration for the expected minimum outdoor temperature at the site.

Solar liquid volume (%)

25

30

35

40

45

Minimum outdoor temperature (ºC)

-10

-13

-17

-21

-26

Do not exceed 50% of water-glycol mixture in any case.

9.0

Instalación y mantenimiento

Instalação e manutenção

Installation and maintenance

Installation et maintenance

Summary of Contents for STS 150-2.0 SL

Page 2: ......

Page 38: ...38 12 0 Notas Notas Notes Notes ...

Page 39: ...39 12 0 ...

Page 40: ... Baxi Calefacción S L U 2016 722138104 0417 CE ...