10

5.3 Installation variants

Explanation of the installation variants depending on the roof construction or design variants.

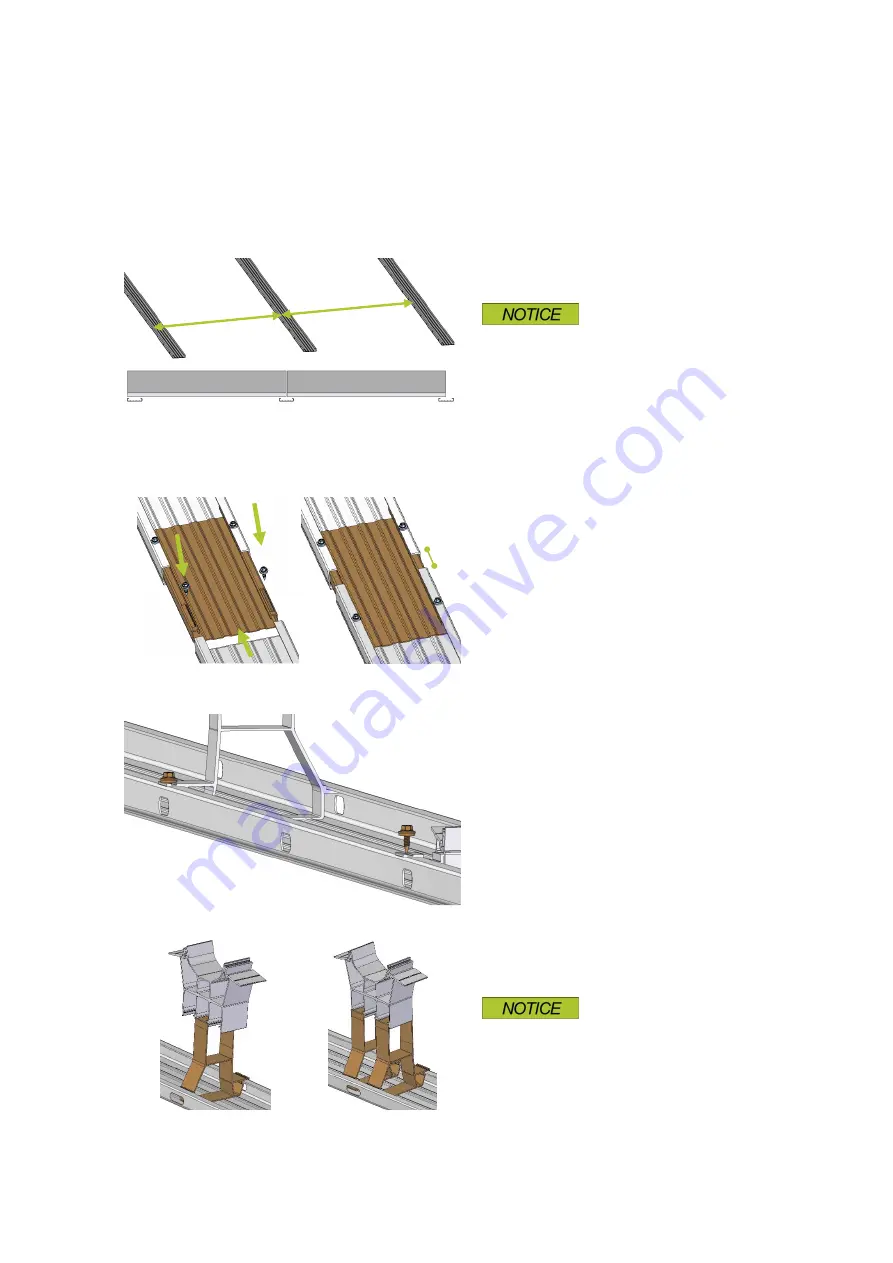

IV 1 – Base troughs on system edge

The first base trough at the system edge /

expansion joint must be installed flush with the

modules, the subsequent base troughs must be

positioned centrally beneath the module joint.

System edge /

expansion joint:

e

A

= module length – 69mm

Module joint:

e

M

= module 12 mm

Prerequisite:

Approval from module

manufacturer for module

clamping

IV 2 – Installation of expansion joints

in the base troughs

Push the base trough expansion joint centrally into

the adjacent base troughs. A gap of 50 mm must

remain between the ends of the rails. Screw the

expansion joints to the base troughs. On the moving

side, the two screws must be screwed into the base

trough so that they are centred in the slots.

Installation expansion joint not below a modul

.

Max.

base trough length with the base trough expansion

joint approx. 34 m, plan for proper expansion joints

after this.

IV 3 – Securing the base foot /

module supports set

Depending on requirements, the base foot and

module support may need to be secured with

screws.

IV 4 – Module supports East-West

Regarding the occurring loads the module support

set of the East-West II system variant must be

installed with a single or a double leg.

Prior to installation, the position (installation axis) of

the components must be determined on the base

trough. Depending on the existing conditions on

site, installation using the installation and removal

tool is recommended.

50

e

M

Edge

e

A

Joint

e

M

Joint

e

A