User Manual

31

Printer calibration

Before start printing, printer calibration must be performed to ensure a reliable first layer and adhesion of the

print to the build surface, and to ensure a proper alignment of both printheads.

NOTE:

Remove the foams under the calibration screws, if you did not do it during printer setup.

Printing surface calibration

Printing surface calibration is a guided process performed by the printer to create a reliable first layer. During this

process, the printer will measure the surface level and it will guide you to adjust the calibration screws of the build

plate.

Watch our

to see how to calibrate the printer.

Tap on the

Next

button to start the process and follow the instructions on the screen:

•

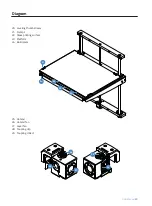

Once the calibration sensors placed on the printheads probed all the four points on the surface, it may be that

the build plate is not completely flat. In this case, the following screen appears indicating which screw needs to

be turned, the direction of the turn and the amount of portions that need to be turned, as indicated in the image

below:

Setup Assistant

i

Summary of Contents for Sigma Series

Page 1: ...User Manual 1 User Manual Sigma Series ...

Page 19: ...User Manual 19 Diagram 9 12 14 11 13 10 15 ...

Page 87: ...MSS 2020 1 ...