User Manual

73

Maintenance

Maintenance is a very important work to keep in mind every day in order to keep the printer in good condition and

always performing at its maximum capabilities.

The following information shows which activities have to be carried out to give the BCN3D Sigma D25 the proper

maintenance and their frequency. Maintenance activities do not take much time and are not complicated. However,

for those that need more attention, more detailed guidelines are provided to guide you through the process.

General maintenance

In general, there are some recommendations when performing general maintenance, but there are some

indications that you must always consider in order to extend product life.

A very important advice is to keep your printer always free of dust and operating in a dry and cool place. We

suggest that the printer operates in an environment at temperatures between 15 and 30 ºC and relative humidity

below 50%. Regarding the filaments, in general we also advise that the spools that are not currently in use are

always stored in an airtight container, with relative humidity below 50% (although this may vary for certain

materials).

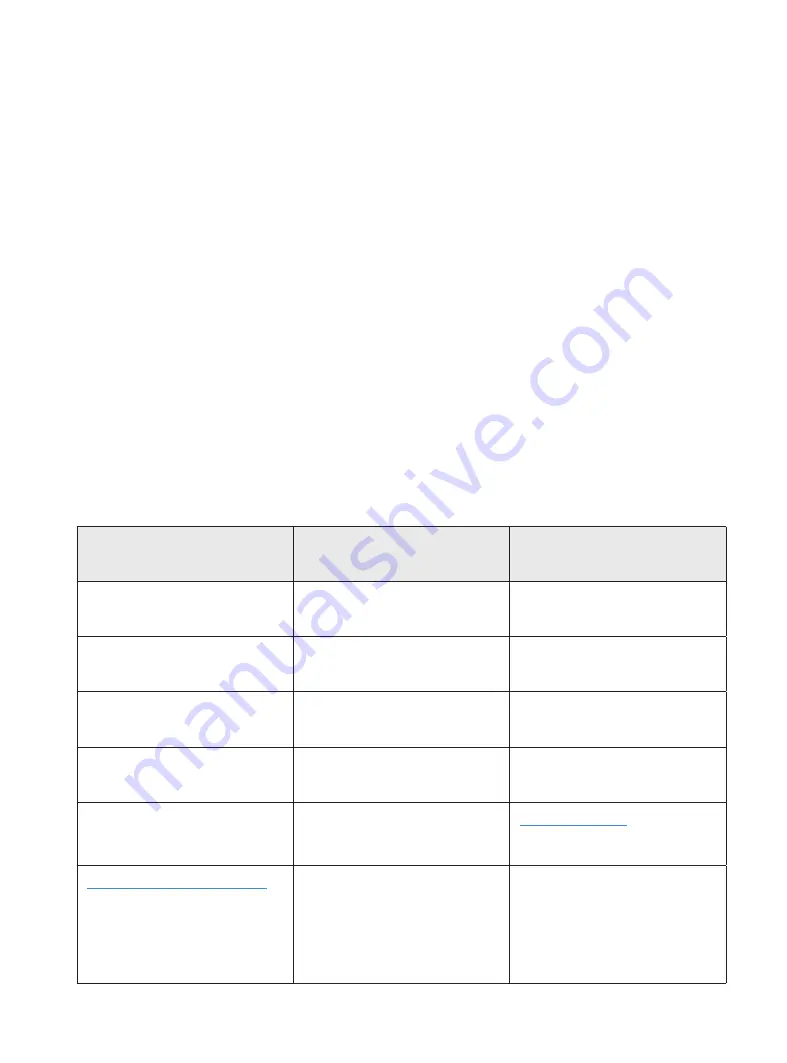

Activity

Frequency

Tools

Clean the printer

Daily

Cloth

Remove filament leftovers spread

inside the printer

Daily

Vacuum cleaner

Compressed air

Remove filament inside the purge

buckets by removing the buckets

Daily

-

Clean dust in hotend fans, cooling

fans and build chamber fan

Monthly

Compressed air

Change HEPA and active carbon

filter

Every 1500 printing hours

(indicated by the printer)

Update printer OS and firmware

If the printer is connected, update

when the update message shows

up.

If it’s not connected, check monthly

on the BCN3D website.

-

Summary of Contents for Sigma Series

Page 1: ...User Manual 1 User Manual Sigma Series ...

Page 19: ...User Manual 19 Diagram 9 12 14 11 13 10 15 ...

Page 87: ...MSS 2020 1 ...