Chapter 1: Overview of HTS Customer Care

3

About the HTS

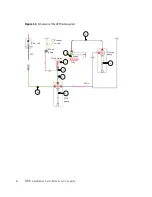

Illustrations of the HTS and a schematic of the fluidics system are provided for

reference. For more detailed information, see your

BD High Throughput Sampler

User’s Guide.

HTS Configurations

The following figures show the front and rear views of the HTS for each

cytometer.

Symptom

Possible Causes

Solution

See...

Wash station

overflows

Wash station clog

Replace the wash

station assembly

Chapter 3

No events

detected

Clog in sample coupler

tubing or tubing

assembly

Replace tubing

assembly components

or sample coupler

tubing

Chapter 5

Leak in sample

coupler

Loose coupler or clog in

coupler tubing

Tighten coupler (see

precautions) or replace

sample coupler tubing

when necessary

Chapter 5

Reduced sheath

flow

Sheath fluid filter is dirty

or clogged

Replace fluidic filter

every six months or

when clogged

Chapter 7

Probe does not

take up sample

Probe might be bent or

clogged

Replace probe tubing

assembly

Chapter 8

Summary of Contents for 644787

Page 3: ...History Revision Date Change Made 23 11165 00 Rev A 1 2010 Initial release ...

Page 4: ......

Page 14: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 28: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 32: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 46: ...THIS PAGE INTENTIONALLY LEFT BLANK ...