Alaris™ GP (Guardrails™) Volumetric Pump

Getting Started

BDDF00535

Issue 1

15/56

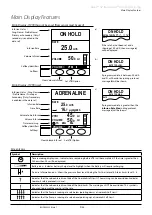

The Alaris Safety Clamp

Alaris Safety Clamp*:

Safety Clamp In Non Occluded Position:

When a new infusion set is removed from packaging the Safety

Clamp will be in this position**:

Safety Clamp

Slider

Safety Clamp Frame

Safety Clamp Tab

FLOW ENABLED

Clamp in NON OCCLUDED

POSITION

Safety Clamp In Occluded Position:

Manually Operating The Safety Clamp

After infusion set is loaded into the Pump, opening the door

activates door hooks which will pull the Safety Clamp slider

out, as shown:

To move the slider into the non occluded position manually, push

up Safety Clamp Tab and push Safety Clamp Slider completely

into Frame:

NO FLOW

Clamp is in OCCLUDED

POSITION

Æ

Ê

1 . Push up

2 . Push

w

w

• Pushing on the Safety Clamp Slider enables full set flow to the patient . Therefore it is recommended to always

close the roller clamp as well .

• However, if gravity infusion is required, push up Safety Clamp Tab and push orange Safety Clamp Slider

completely into Frame to enable flow . The gravity infusion can be regulated using the roller clamp on the set .

*

Hereinafter referred to as to as 'Safety Clamp' .

**

This is necessary to avoid tube damage during storage and to ensure correct sterilisation and allows immediate priming .