8

EKF Series 300/500/600

GB

Safety equipment

Overheat protection (EKF series 500/600

only)

The machine is also protected against

overheating. If the machine becomes too

hot, it switches off automatically.

Perform the following steps before continu-

ing to work with the machine:

■

Allow the machine to run at idle for

approx. 2 minutes.

The machine is then ready for operation

again.

Swarf guard (EKF series 500/600 only)

The machine is equipped with swarf

protection that largely prevents swarf from

spinning out.

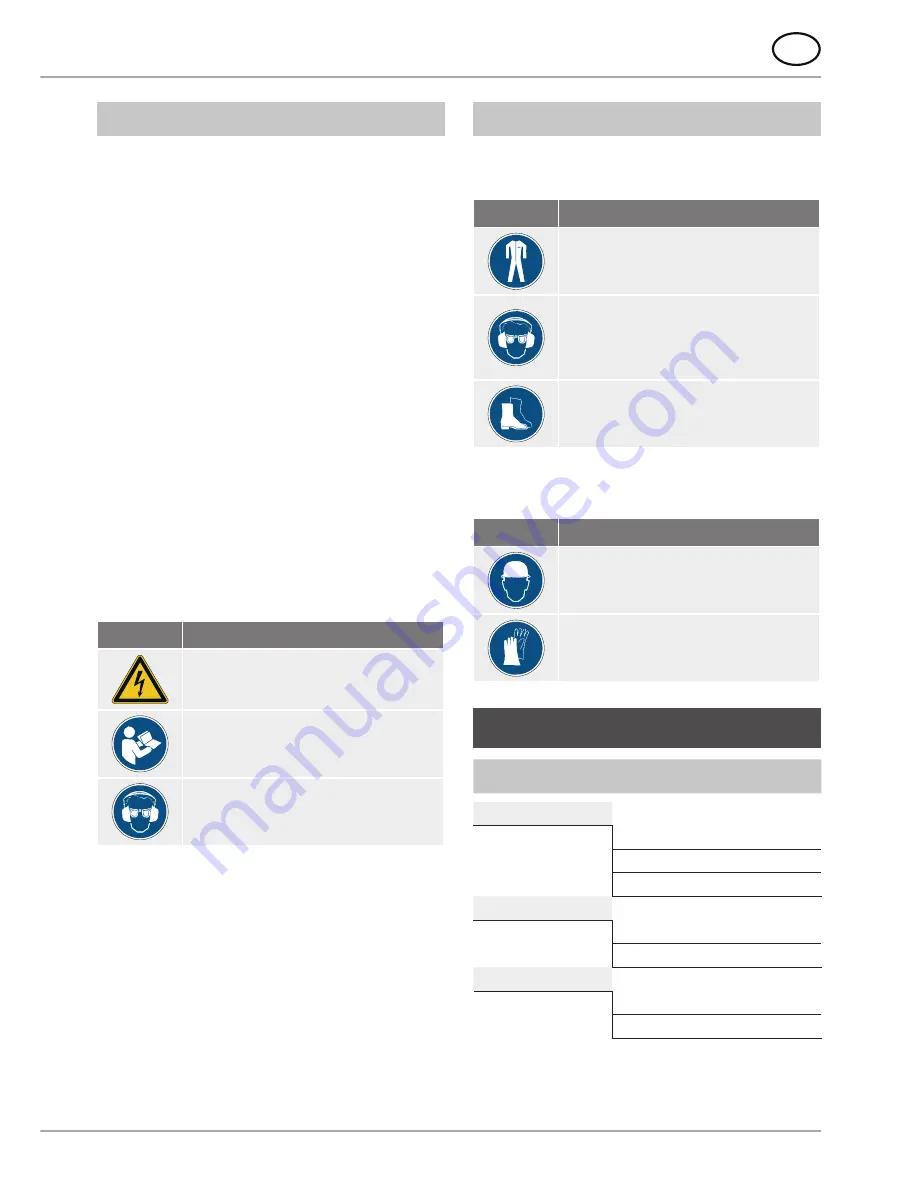

Symbols on the machine

The symbols on the machine have the

following meaning:

Symbol Meaning

Electric shock hazard!

Read the operating instructions

before beginning work!

Wear protective goggles and

ear protection!

Personal protective equipment

Wear the following protective equipment at

all times when operating the machine:

Symbol Meaning

Close-fitting work protection

clothing with a low tear strength

Goggles for protecting eyes

against flying parts and liquids

and ear protection in areas with

noise emission >80 dB(A)

Safety shoes for protecting feet

against falling objects.

Also wear the following protective equip-

ment during special work:

Symbol Meaning

Helmet for protecting your head

against falling objects

Gloves for protection against

injuries

Model overview

Series

Machine description

EKF Series 300

EKF 300

EKF 450

EKF 452

EKF Series 500

EKF 530

EKF 545

EKF Series 600

EKF 630

EKF 645

Safety