USER MANUAL

5

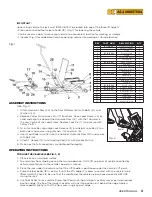

TROUBLESHOOTING

*For purging air, see Purging Air Instructions on page 2.

PROBLEM

CAUSE

SOLUTION

Jack will not lower completely. 1. Air in hydraulic system.

2. Release valve is stuck.

1. Purge air from hydraulic system.*

2. Transfer weight load and clean valve.

Jack will not lift to full height.

1. Oil level is low.

2. Air in hydraulic system.

1. Fill to recommended level.

2. Purge air from hydraulic system.*

Weak Lifting.

1. Air in hydraulic System.

2. Dirty oil.

1. Purge air from hydraulic system.*

2. Change oil. Use SAE 5W.

Jack will not lift load.

1. Excessive weight.

2. Oil level is low.

1. Decrease weight or change to a higher capacity jack.

2. Fill to recommended level.

TWO YEARS LIMITED WARRANTY

WARRANTY INFORMATION

For a period of two (2) years from your purchase date, BE AG & INDUSTRIAL will repair or replace (at its

option) without charge, your BE AG & INDUSTRIAL product if it was purchased new and the product has failed

due to a defect in material or workmanship which you experienced during normal use of the product. This

limited warranty is your exclusive remedy.

If this BE AG & INDUSTRIAL product is altered, abused, misused, modified, or undergoes service by an

unauthorized technician, your warranty will be void. We are not responsible for damage to ornamental designs

you place on this BE AG & INDUSTRIAL product and such ornamentation should not cover any warnings or

instructions or they may void the warranty. This warranty does not cover scratches, superficial dents, and

other abrasions to the paint finish that occur under normal use.

To access the benefits of this warranty, contact the dealer or retailer where the unit was purchased. For

further assistance, you can contact BE AG & INDUSTRIAL at warranty@brabereq.com for confirmation that

this warranty applies. Thereafter, you may be advised to return the product under warranty, freight prepaid, to

the dealer or directly to the BE AG & INDUSTRIAL service department.

Subject to the law in your state:

(1) Your sole and exclusive remedy is repair or replacement of the defective product as described above.

(2) BE AG & INDUSTRIAL is not liable for any incidental damages, including but not limited to, lost profits and

unforeseeable consequences.

(3) The repair and replacement of this product under the express limited warranty described above is your

exclusive remedy and is provided in lieu of all other warranties, express or implied. All other warranties,

including implied warranties and warranties of merchantability or fitness for a particular purpose are

disclaimed and, if disclaimer is prohibited, these warranties are limited to two years from your date of

purchase of this product.