6

USER MANUAL

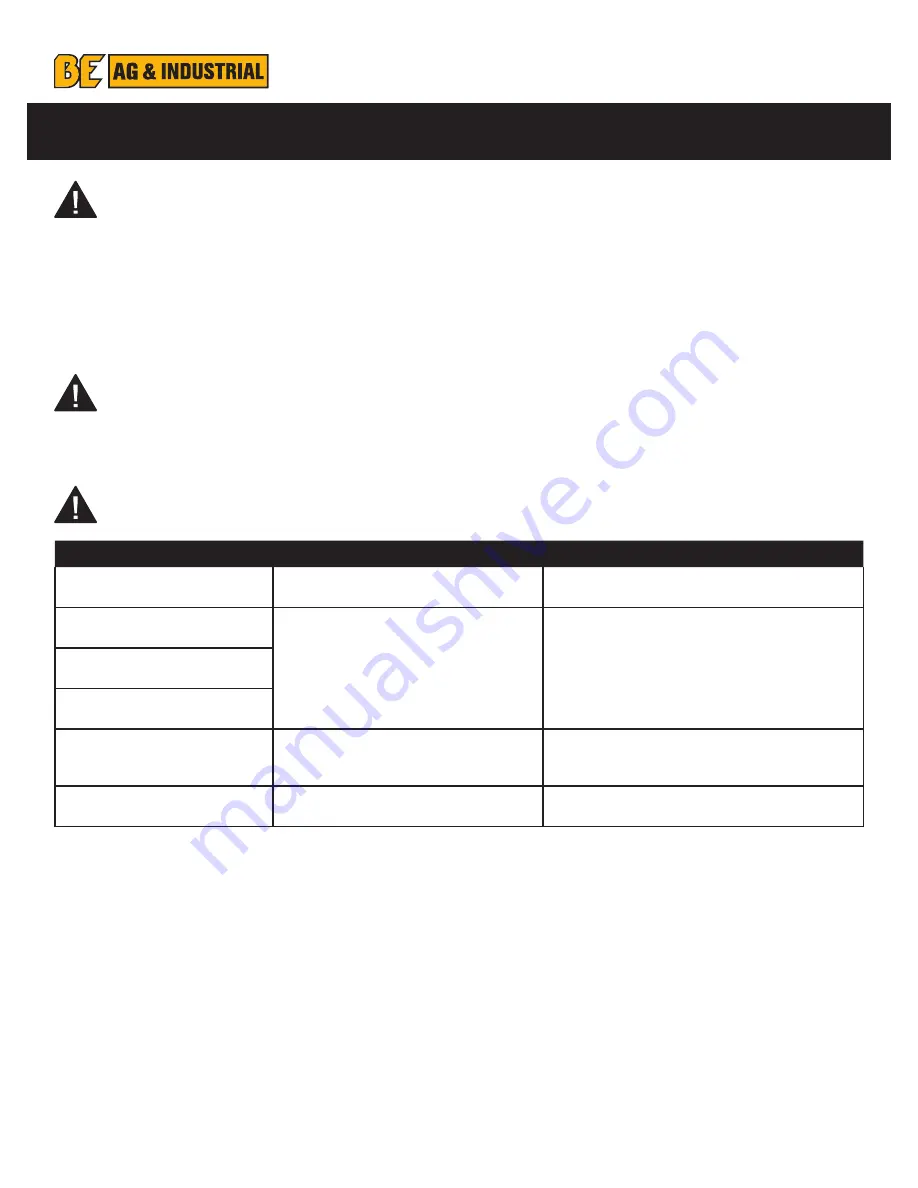

SYMPTOM

POSSIBLE CAUSES

SOLUTION

JACK WILL NOT WORK

DIRT ON VALVE SEALS/ WORN

SEALS

REPLACE WITH NEW SEALS

JACK WILL NOT PRODUCE

PRESSURE

AIR BLOCK

1) OPEN THE RELEASE VALVE AND

REMOVE DIP STICK

2) PUMP HANDLE A COUPLE OF FULL

STROKES AND CLOSE RELEASE VALVE

3) REPLACE DIP STICK

JACK UNIT FEELS

UNSTEADY UNDER LOAD

JACK WILL NOT LOWER

COMPLETELY

JACK WILL NOT PRODUCE

PRESSURE

THE RESERVOIR COULD BE

OVERFILLED OR LOW ON

HYDRAULIC OIL LEVEL

TO CHECK THE OIL LEVEL. REMOVE

THE DIPSTICK AND TOP UP OR DRAIN

TO THE CORRECT LEVEL.

JACK UNIT FEELS

UNSTEADY UNDER LOAD

THE PUMP SEAL COULD BE

WORN OUT

REPLACE CUP SEAL WITH NEW ONE

INSPECTION, STORAGE & TROUBLESHOOTING

INSPECTION

TROUBLESHOOTING

STORAGE

Owners and/or operators should be aware that repair of this equipment may require specialized knowledge

and facilities. It is recommended that an annual inspection of the product be made by a manufacturers or

supplier’s authorized repair facility and that any defective parts, decals, or safety labels or signs be replaced

with manufacturers or supplier’s specified parts.

This device shall be inspected immediately if the device is believed to have been subjected to an abnormal

load or shock. It is recommended that this inspection be made by a manufacturers or supplier’s authorized

repair facility.

When the body repair kit is not in use, the pump unit should be stored with the release valve open in a dry

location on a level surface

Summary of Contents for 35.100.004

Page 4: ...4 USER MANUAL SUGGESTED SYSTEM ASSEMBLIES...

Page 17: ...USER MANUAL 17...