BE-LS40TS390 USER MANUAL

25

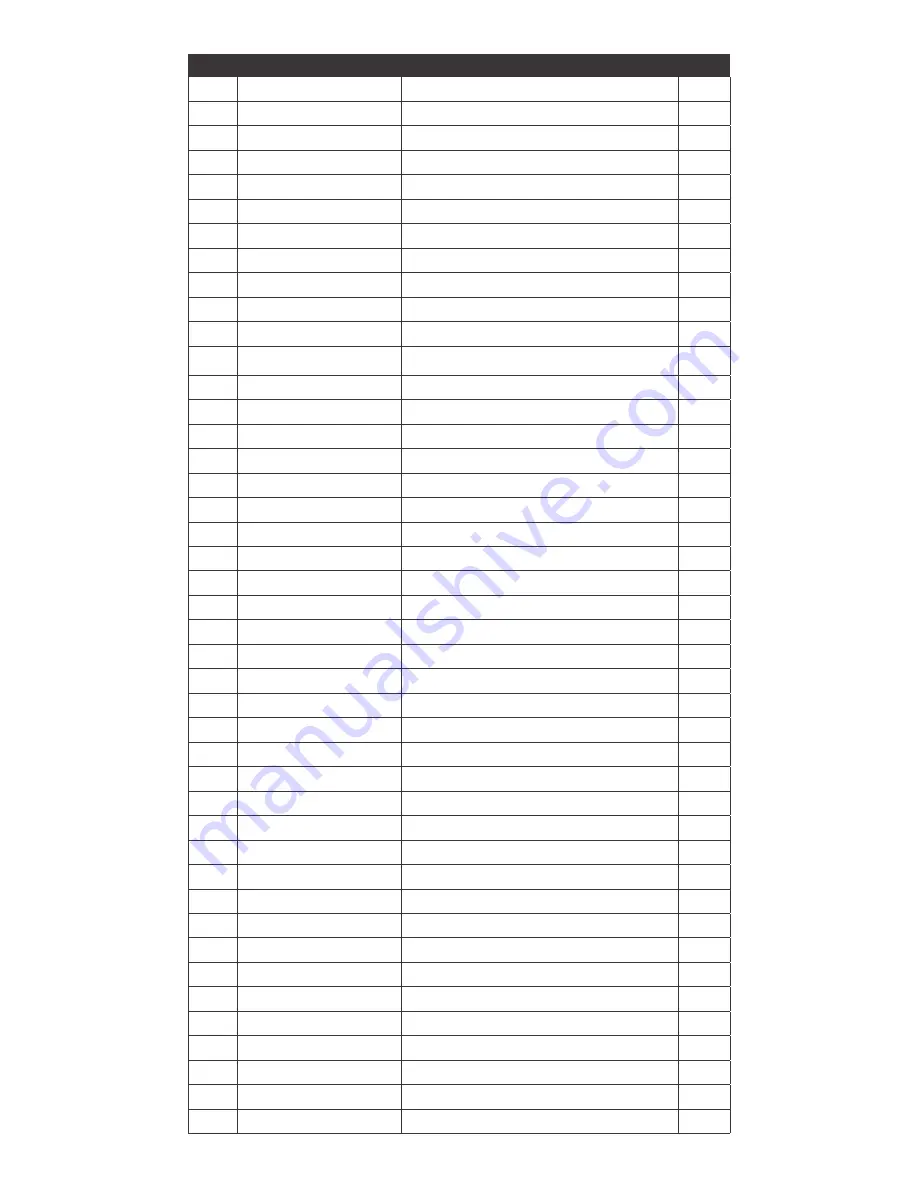

REF PART NO.

DESCRIPTION

QTY

44

LSA22-15000

Rear Support Leg

1

45

9101-10075-DX8.8

Hex Bolt M10x75

5

46

LSP22-16000

Hitch Pin

1

47

LSP25-00012

R Pin

1

48

LSA22-00015-DX

Hinge Pin

1

49

9404-04040-DX

Cotter Pin Ø4x40

1

50

LSP25-13000

Oil Bolt

1

51

LST37-10000

Oil Tank

1

52

9304-62000-FH

Circlip for Shafr Ø62

1

53

LSA22-18000

Right Protection Fender

1

54

9101-12040-DX8.8

Hex Bolt M12x40

4

55

9206-12000-DX

Hex Lock Nut M12

7

56

LSA22-17000

Left Protection Fender

1

57

9404-03030-DX

Cotter Pin Ø3x30

2

58

9301-20000-DX

Flat Washer Ø20

2

59

LSP25-00008-DX

Safety Pin

2

60

9399-12000-DX

Thick Flat Washer Ø12

4

61

LSA22-13000

Safety Chain with Hook

2

62

Z103

2” Coupler

1

63

9101-12130-DX8.8

Hex Bolt M12x130

2

64

9101-12090-DX8.8

Hex Bolt M12x90

1

65

LST37-06000

Tow Bar

1

66

LSP25-00010-DX

Oil Plug

1

67

LSP30-00007

Oil Filter

1

68

LST37-04000

Engine Mounting Plate

1

69

LSP30-00006

Rubber Washer

1

70

LSP30-15000-DX

Oil filter Mounting Plate

1

71

9101-06020-DX8.8

Hex Bolt M6x20

6

72

9306-06000-DX

Lock Washer Ø6

6

73

9301-06000-DX

Flat Washer Ø6

6

74

LSP25-00020-FH

Slotted Nut M20

2

75

LSP25-00009-DX

Axle Cap

2

76

NS10-02002-DX

Jockey Wheel Handle Bushing

1

77

LSP25-14000

Wheel / Tire Assembly

2

78

LST37-08000

Outside Wheel Bushing

1

79

LST37-09000

Moving Pipe

1

80

NS10-02001

Screw Rod

1

81

LST37-00016

Oil Return Pipe Connector

1

82

9121-06010-FH

Screw M6x10

1

83

LSP35-02001

Gasoline Engine 13HP

1

84

LSP35-00001

Polyurethane Block

4

85

9302-10000-DX

Big Flat WasherØ10

4

86

9101-08025-DX8.8

Hex Bolt M8x25

4