12

Solutions of Fault

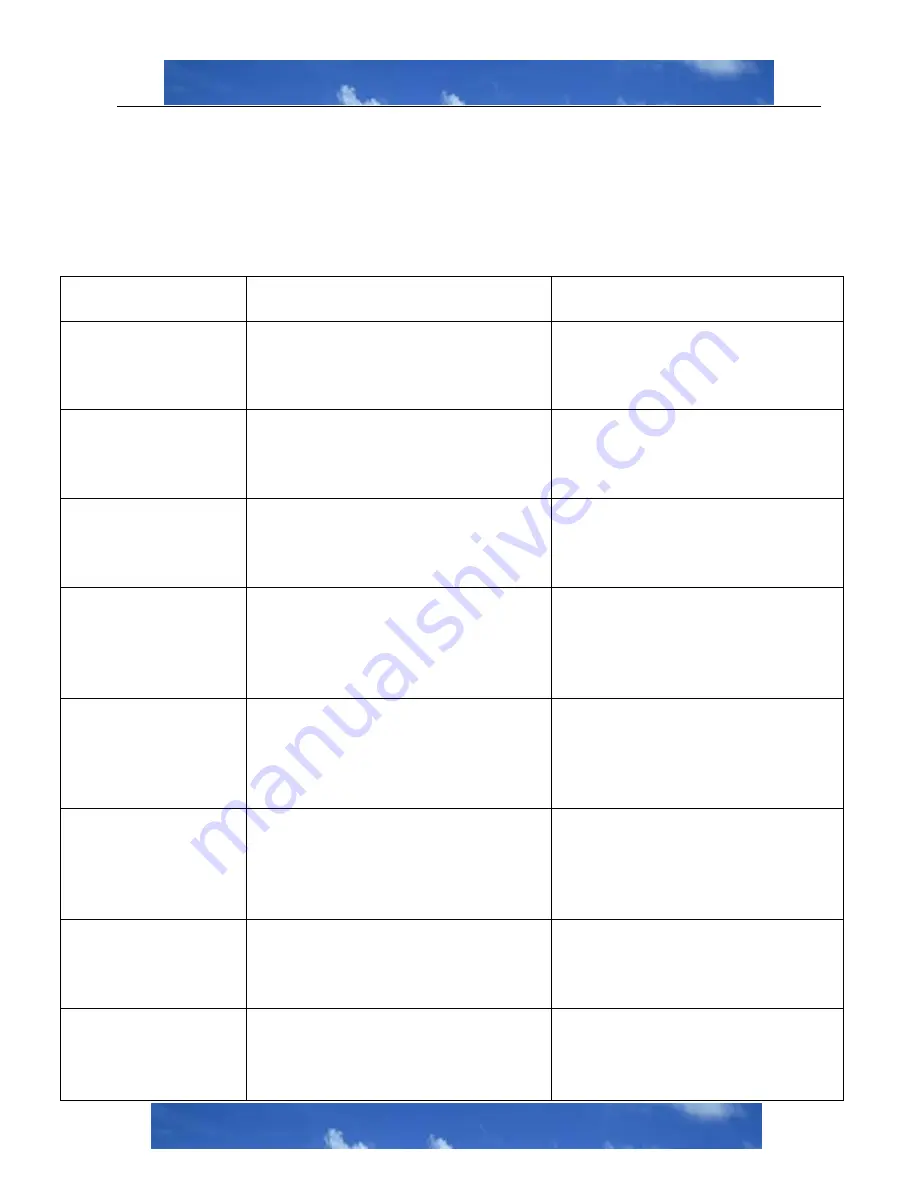

Phenomenon

Reason

How to Solve the problem

No power supply

1. The electric leakage switch

was

breaked off

2. The Fuse be break off

1. Check and eliminate the malfunction,

restart the spa

2. Please change fuse

No display on control

panel

1. The plug which connected with the

panel loose or disconnected

2. The Panel happened with malfunction

1.

to connect the plug of the control

panel and the main box

2.

Change a new control panel

LED light not work

1.

Power of the light be break off

2.

Fuse be break off

3.

light be burn

1.

To check if cable of the light is well

connected with main box or not

2.

Change a fuse

3.

Change a new lampwick

Ozone not work

1.

Ozonater burn

2.

Fuse be break off

3.

Cable of the ozonater be cut off

1.

Change a new ozonater

2.

change a fuse

3.

check if the cable of the main power

is connected with the main box or

not.

Displaied “E1””FF” in

control panel

1. temperature detector be cut off or

shortcirculate

2. plug of the temperature detector be

nundated by water

1. Connect the temperature detector

2.Change a new temperature detector

being incapable of

activate water pump,and

water pump icon

flashing

1.water not achieve the appointed level

2. water detector not connect well

1.

To add more water to make it up to

the water detector

2.

To re-connect the line of water

detector

Heater not work, and

heating icon on panel

flashing

1.

setting water temperature lower then

the water temperature

1.

set the temperature degrees higher

than the water in tub

temperature(between 15 and 43 °C

。

Leakage

1. silicon plaster not good

2. PVC plaster not good

3. Blow out of the water pipe

1.

To remove the jets then re-install

one

2.

To plaster once again

Change water pipe

Summary of Contents for SPA-520

Page 1: ...1 HOT TUB Model SPA 520 OPERATING INSTRUCTION...

Page 13: ...13...

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...