1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com

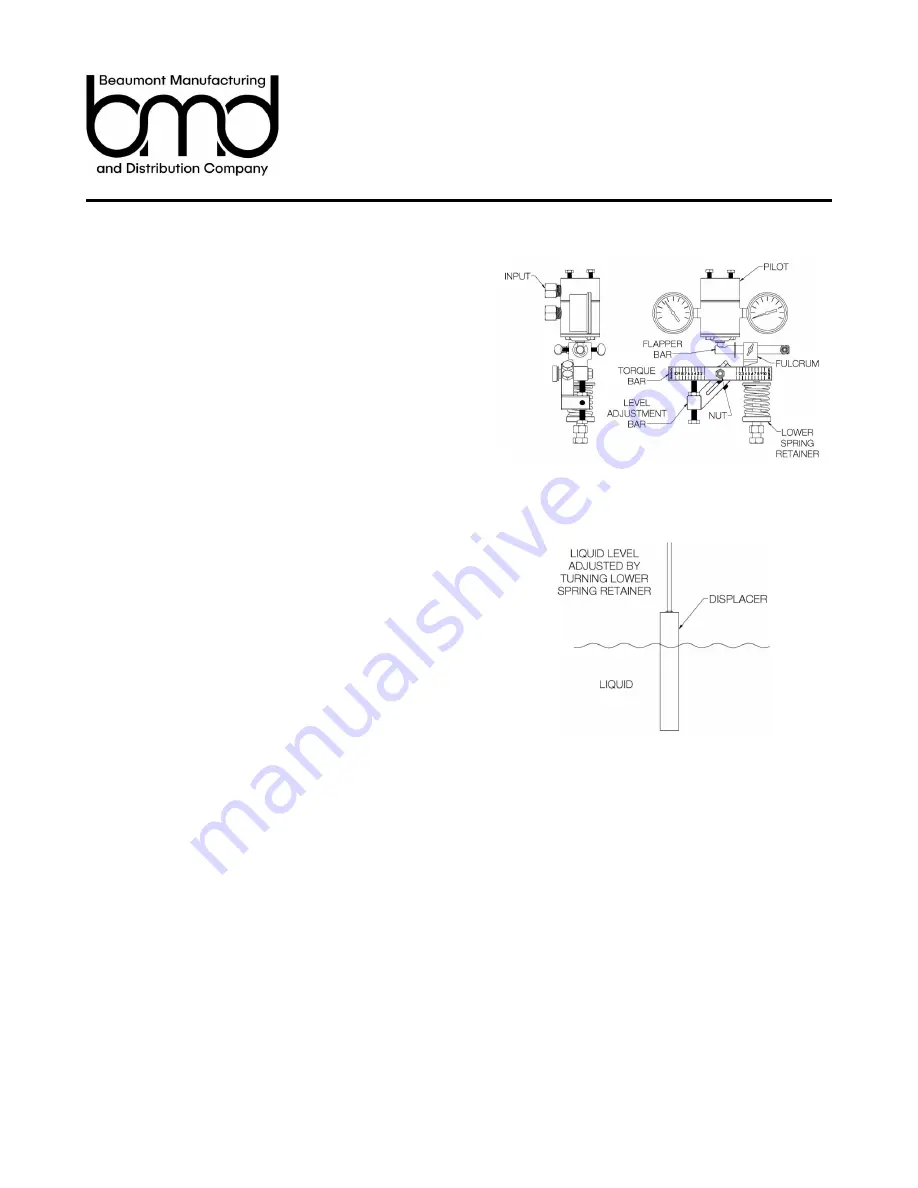

Model LC10 Operation

Principles of Operation

The LC10 uses Archimedes' principle in order to detect the level of

liquid in a vessel. The Displacer weighs less when submerged in a

liquid, because of the buoyant force acting on the Displacer when it is

submerged. Since the weight of the Displacer is balanced by the

LC10 Spring, the buoyant force from the liquid is enough to lift the

Displacer and Arm upward rotating the Level Adjustment Bar. The

Level Adjustment Bar pushes on the Torque Bar which acts upon the

Fulcrum on the Level Adjustment Bar. The Level Adjustment Bar then

pushes the Pilot Pin triggering the Pilot.

Level Adjustment

When using an LC10 with a vertical Displacer orientation, the liquid

level in the vessel can be adjusted by turning the Lower Spring

Retainer as shown in Figure 4. Turning the Lower Spring Retainer

changes the amount of load provided by the Spring which in turn

changes the amount of support provided to the Displacer’s weight.

Turning the Lower Spring Retainer clockwise provides less spring load

and less offset of the displacers weight. This means that the liquid will

have to rise higher on the Displacer in order to lift it and trigger the

LC10. Turning the Lower Spring Retainer counter

-

clockwise provides

more spring load meaning the liquid level does not need to rise as

high on the Displacer to trigger the LC10. Therefore turning the Lower

Spring Retainer clockwise raises the liquid level in the vessel, and

turning it counter

-

clockwise lowers the level.

Note that amount that the level can be adjusted is limited by the

length of the Displacer.

Direct vs Reverse Acting (See Figure 6)

A direct acting LC10 arrangement will increase the Pilot output as the

Displacer is lifted. Reverse acting arrangement will decrease the Pilot

output as the Displacer is lifted.

Figure 4

Figure 5

Reverse

Direct

Figure 6