1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com

Model LC10 Maintenance

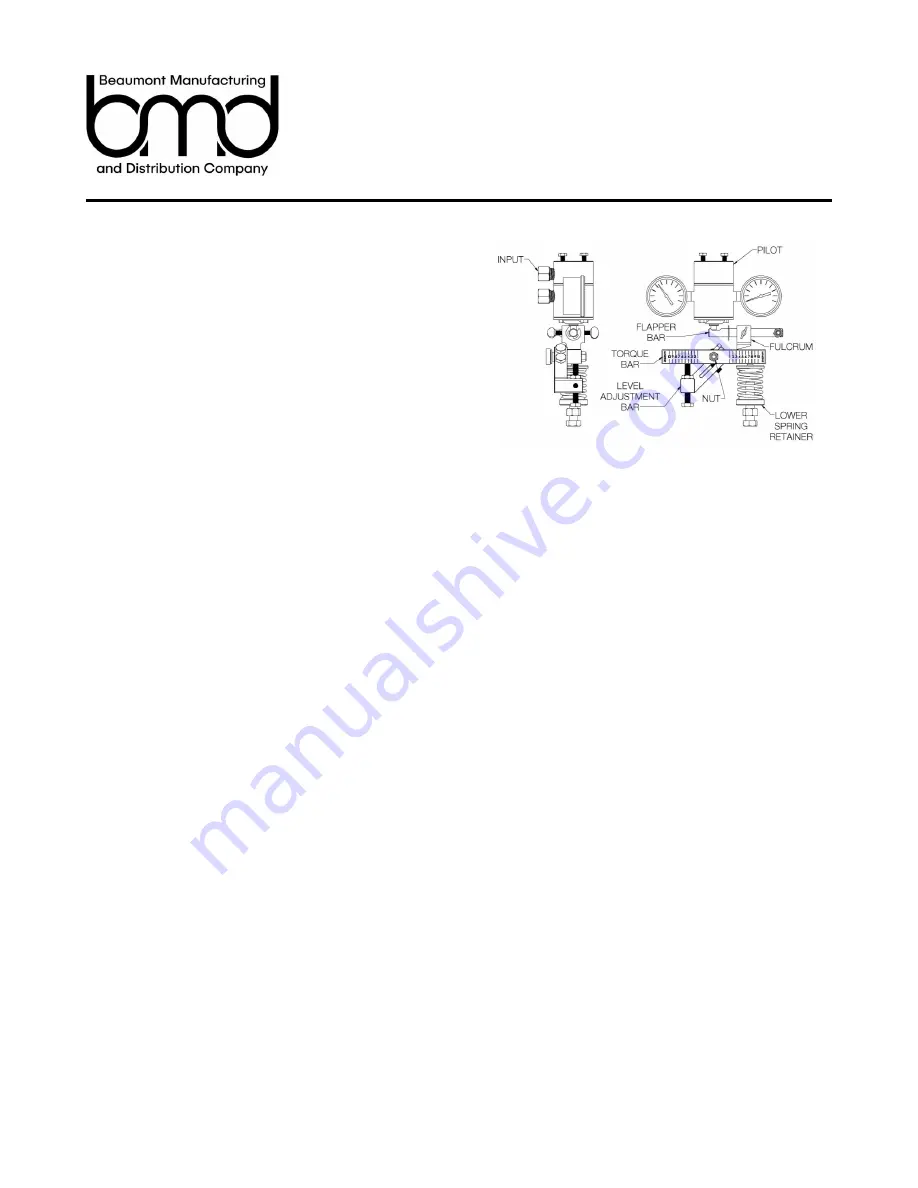

Setting the LC10

To set the LC10 first connect an airline to the input of the Pilot. Next,

adjust the Lower Spring Retainer so that, when the Arm is in its set

position and then lifted, the Flapper Bar triggers the Pilot.

Mounting Change

The LC10 is field reversible which is convenient for arrangement

changes. To switch the LC10 from left to right or vice versa, first

remove the nut holding the Torque Bar and Level Adjustment Bar on

the Shaft. Next, remove the Torque Bar and Level Adjustment Bar.

The Body is held on by two hex head screws. Remove the screws

and rotate the Body to the desired orientation and reinstall the screws

to secure the Body. The Level Adjustment Bar will need to be rotated

clockwise or counter clockwise depending on the initial setup. The

screw will need to be removed from the Level Adjustment Bar and

threaded into the correct hole once the Bar has been rotated. The

Spring, Upper and Lower Spring Retainer, and Screw will swap to the

other side. Put the Level Adjustment Bar and Torque Bar back on the

Shaft and use the nut to secure them. Finally, The Fulcrum Assembly

will need to be moved to the opposite side. Unscrew the nut holding it

on the stud and simply swap to the other side. Reference Figure 11.

Action Change

To change an LC10 from reverse to direct or vice versa simply

unscrew the nut holding on the Flapper Bar. Remove the Flapper Bar

and move it to the other side of the Case. Don’t forget to swap the

Thumb Screw around to the front. Re

-

install the nut taking care not

to over tighten it. Overtightening the nut will hinder the Flapper Bar

from rotating and will cause the unit to malfunction. For best

performance the nut should be snugged up against the Flapper Bar

then backed off about 1/8 of a turn.

Body Maintenance (See Figure 12)

To replace the soft goods in the Body of the LC10 unscrew the nut

holding on the Torque Bar and Level Adjustment Bar, remove them

from the Shaft, and remove the Body from the Case by unscrewing

the two hex head screws. Once the Body is removed, unscrew both

Bearing Blocks to reveal the two O

-

rings and Backup Ring on each

side. Remove the old O

-

rings and Backup Rings and replace them

with the new ones provided in the repair kit. Before installing the new

O

-

rings, grease them with multi

-

purpose synthetic grease for reduced

wear and longer life expectancy. Reinstall the Bearing Blocks into the

Body and attach it back to the Case securely tightening the two hex

head screws. Put the Level Adjustment Bar and Torque Bar back on

the Shaft and secure them with the nut.

Figure 10

Figure 12

Figure 11

Left Hand Reverse

Right Hand Reverse

Left Hand Direct

Right Hand Direct