1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com

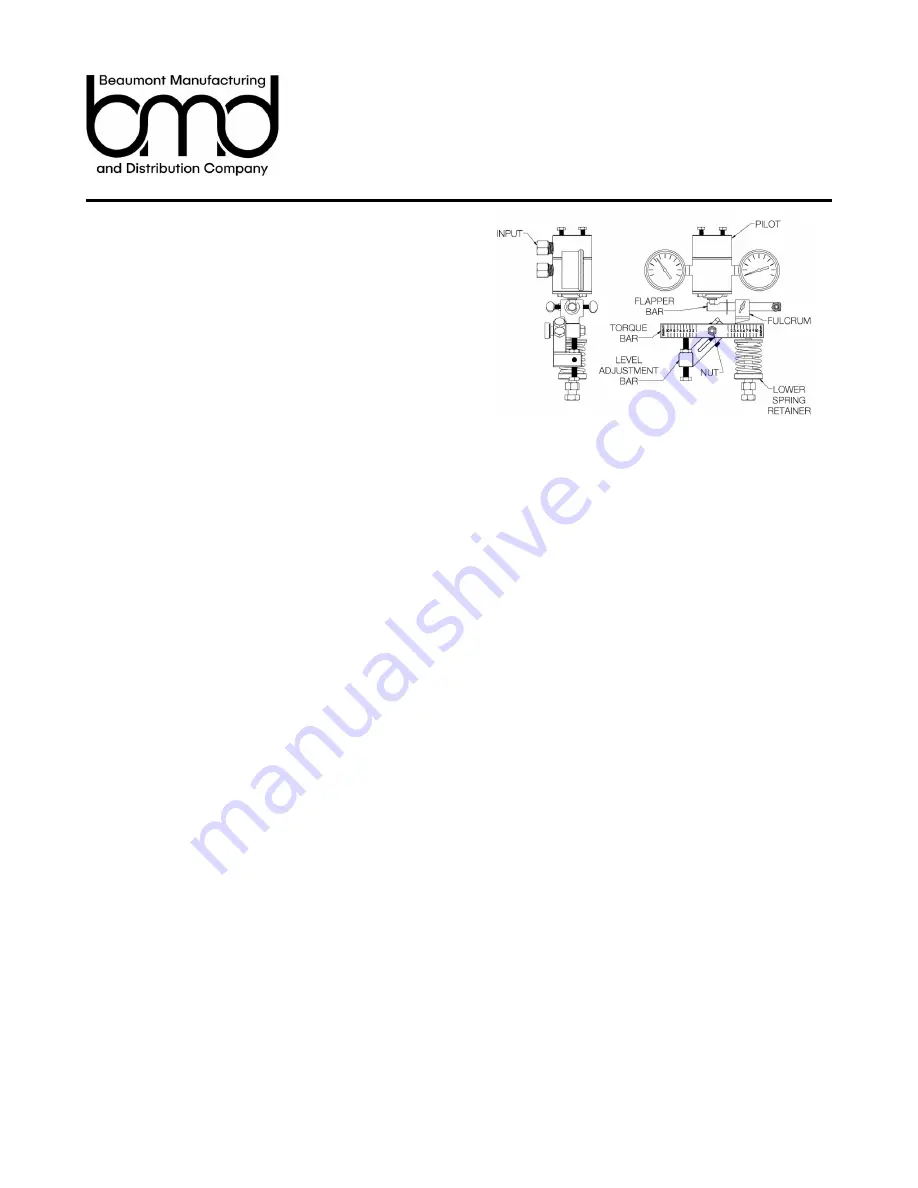

Model LC10 Maintenance Cont.

Pilot Change

Standard Case (See figure 13)

To remove the Pilot, first turn the Lower Spring Retainer all the way to

the bottom to relieve the tension on the Spring. Next, unscrew the two

screws located on top of the Case. Push down the Torque Bar on the

Spring side as far as it will go. This will allow the Pilot to be removed.

Put in the new Pilot, and replace the upper screws to hold it to the top

of the Case. Make sure that the Flapper Bar is positioned so that the

Pilot Pin rests in the slot. The Pilot Pin should be able to move freely

in the slot without binding as the Flapper Bar moves up and down .

Sealed Case (See Figure 14)

To remove the Pilot, first turn the Lower Spring Retainer all the way to

the bottom to relieve the tension on the Spring. Next, unbolt the Pilot

Plate that covers the front of the Pilot. Push down the Torque Bar on

the Spring side as far as it will go. This will allow the Pilot to be

removed. Remove the Gasket behind the Pilot. To reassemble replace

the Pilot Gasket with a new one and put in the new Pilot. Put the Pilot

Plate back on and reinstall the pilot plate screws. Make sure that the

Flapper Bar is positioned so that the Pilot Pin rests in the slot. The

Pilot Pin should be able to move freely in the slot without binding as

the Flapper Bar moves up and down .

Pilot Repair (See Figure 15)

Remove the two screws holding together the Pilot to expose the

components within. When replacing the components, the Gasket

needs to be checked so that the orientation of the cutouts match the

holes on the Body. Reassemble and test the Pilot with a supply line to

check for leaks before installing back into the Case. Mount the Pilot

back into the Case with the two screws and make sure the Flapper

Bar is positioned correctly on the Pilot Pin.

Figure 13

Figure 15

Figure 14