1/2019

Installation, Operation, and

Maintenance Instructions

www.beaumontmanufacturing.com

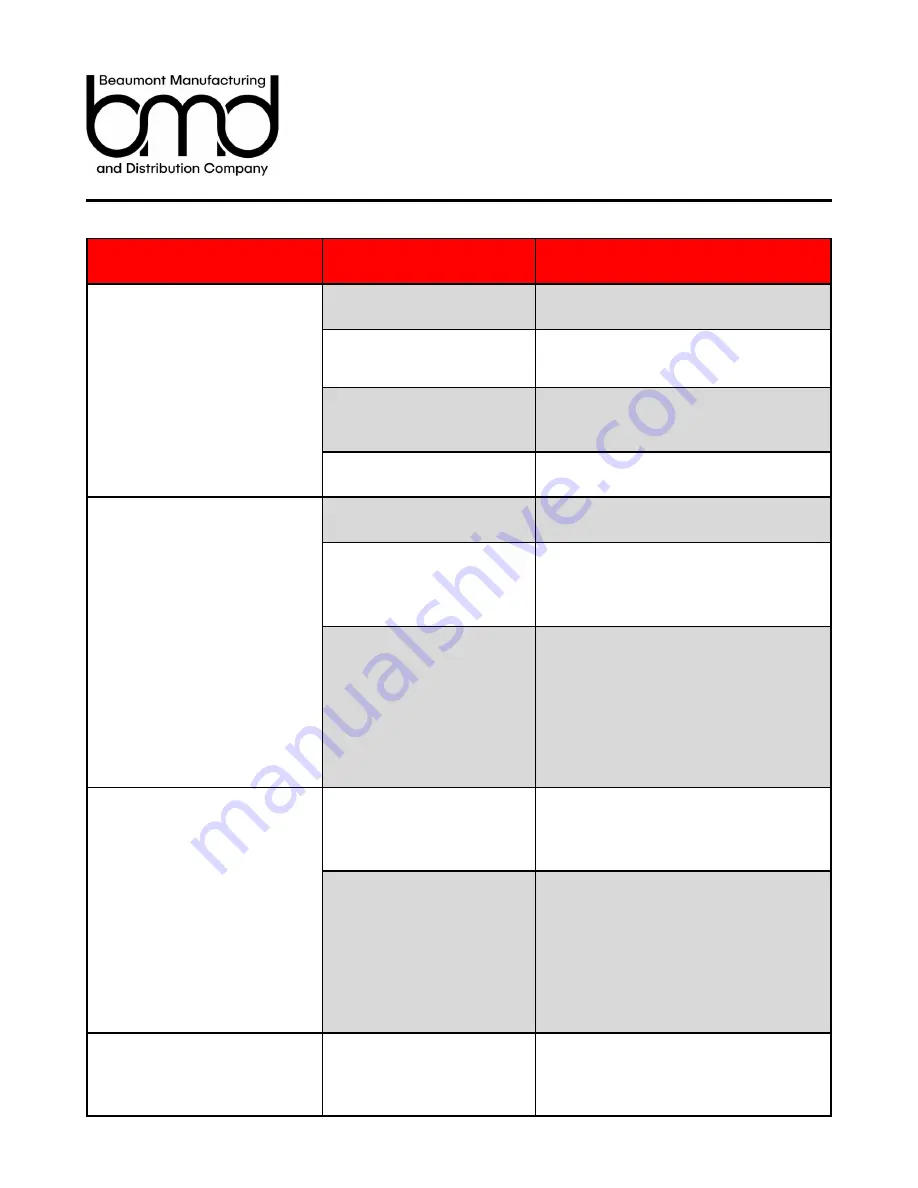

Model LC10 Maintenance Cont.

Symptom

Probable Cause(s)

Corrective Action(s)

Air leaking through pneumatic pilot

continuously

Snap Pilot: Ball isn't seating

properly

Connect an air supply line to the inlet port on the

Pilot and actuate the pilot 2

-

4 times

Throttle Pilot: Lower pin (peanut)

not seating

Connect an air supply line to the inlet port on the

Pilot and actuate the pilot 2

-

4 times.

Debris on the sealing surfaces

Clean out the inside of the top cap and body of

any debris and actuate the pilot 2

-

4 times with

air connected to the inlet port.

Snap ring not in the groove on the

pin

Check to be sure the snap ring is sitting in the

groove on the pin.

Pilot output gauge not indicating an

output pressure signal on a direct

acting controller when the fluid level is

above displacer or on a reverse acting

controller when the fluid level is below

the displacer.

The gasket is not installed properly

Ensure the gasket cutouts match the holes in the

body when replacing.

The spring isn't compressed

enough and therefor not applying

enough pressure on the torque

bar.

Turn the lower spring retainer counter

-

clockwise

until the output pressure signal is indicated on

the gauge. Verify when the fluid level falls or rises

for direct and reverse acting, respectively.

The displacer arm is set too low or

the displacer is bottoming out on

something inside the vessel

Check the displacer arm by moving the level

adjustment bar up and down. If the level

adjusting bar only moves in one direction it

indicates the displacer arm is sitting at either the

top or bottom of the vessel connection. If it

moves too freely, the displacer is no longer

connected to the arm. Re

-

center the displacer

arm in the vessel connection.

Pilot output gauge not indicating an

output pressure signal on a direct

acting controller when the fluid level is

above displacer or on a reverse acting

controller when the fluid level is below

the displacer.

The spring is compressed too

much and therefor applying too

much pressure on the torque bar.

Turn the lower spring retainer clockwise until the

output pressure signal is relieved on the gauge.

Verify when the fluid level falls or rises for direct

and reverse acting, respectively.

The displacer arm is set too high

or the displacer is bottoming out

on something inside the vessel

Check the displacer arm by moving the level

adjustment bar up and down. If the level

adjusting bar only moves in one direction it

indicates the displacer arm is sitting at either the

top or bottom of the vessel connection. If it

moves too freely, the displacer is no longer

connected to the arm. Re

-

center the displacer

arm in the vessel connection

Controller does not repeat at the same

fluid level after each dump and

sometimes fails to either dump or

shut

-

off

Debris has accumulated inside the

level control body

Remove the controller from service and clean the

body with a solvent

Table 1. Trouble Diagnosis