Deleting both limit positions

Any additional functions that may have been set are deleted at the same time, or are reset

to the factory default settings.

Open/close the shading solution to a point between the limit positions.

Press the programming button and keep it pressed.

Then press down the travel button and keep it pressed.

Now release the programming button, but continue to keep the travel button pressed.

Next press the programming button again.

▻

The tubular drive confirms.

►

Both limit positions are deleted.

Adjusting the limit positions with a rotary switch or a locking button

Intelligent installation management

Completion of installation following automatic setting of limit position "Stop"

The drive saves the limit position "Stop" permanently once the it has been reached 3 times in succession. Installation is then com-

plete.

Limit position status indicator

A brief stopping and restarting indicates that no limit position has been set in that direction of movement.

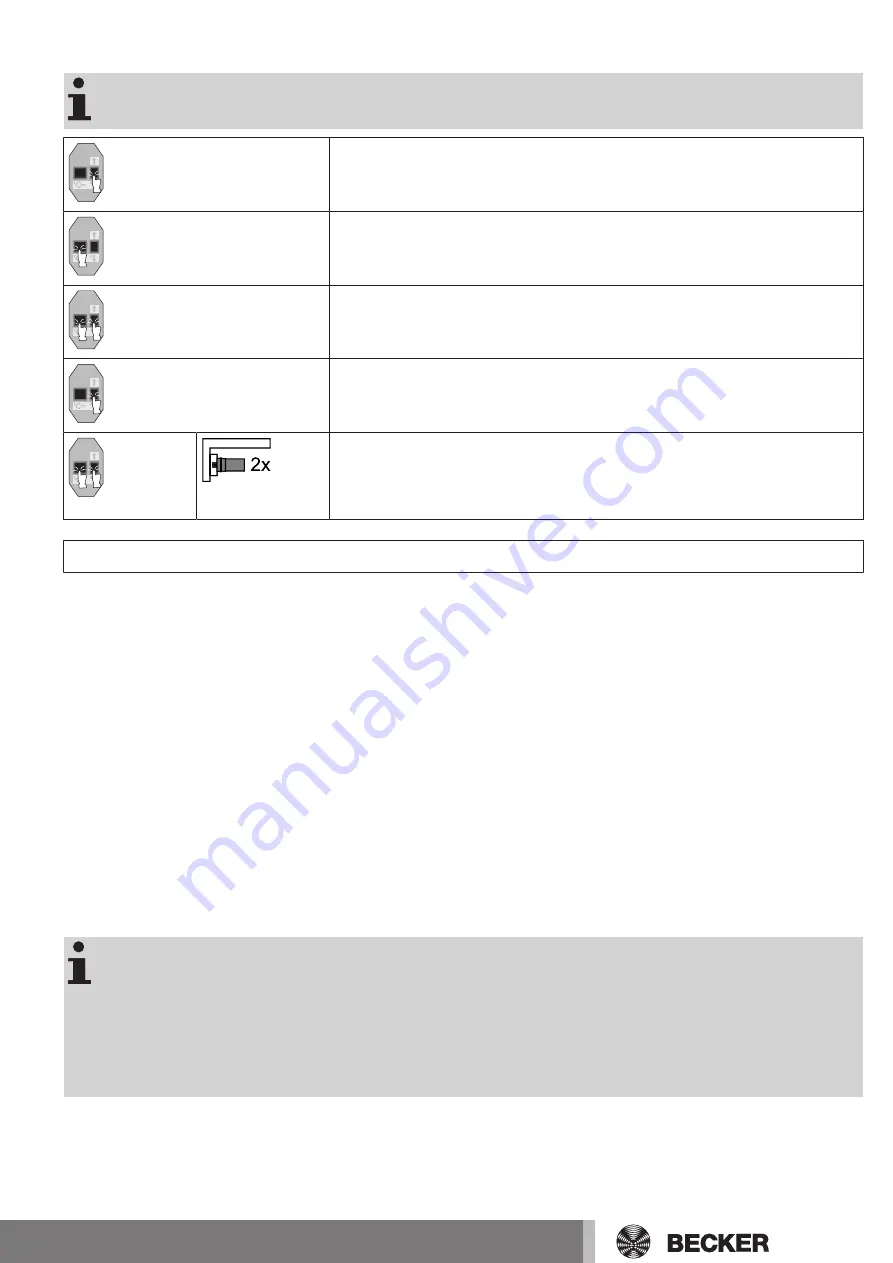

There are several ways to set the limit positions:

•

Upper stop to lower stop

•

Upper point to lower point

•

Upper stop to lower point

•

Upper point to lower stop

The limit position becomes fixed after the tubular drive has turned off automatically in the desired position three times.

If the tubular drive switches off prematurely while opening or closing due to an obstruc-

tion, the obstruction can be cleared by reversing a short way and removing the obstruc-

tion. The desired limit position can then be set by opening/closing again.

When first installing using springs and adjusting the limit position "...to lower stop", the

barrel in the lower limit position turns approx. 1/4 of a turn further than usual. In doing so,

the tubular drive is able to automatically detect the use of anti-lifting devices or springs.

The tubular drive switches off automatically.

13 - en

Summary of Contents for enocean R8-17

Page 23: ...Declaration of conformity 23 en ...

Page 24: ...Declaration of conformity 24 en ...

Page 28: ......