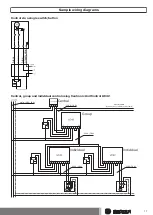

Disassembling the plug-in connecting cable for tubular drives dia. 45 and dia. 58

Caution

Prior to disassembly, the power supply to the connecting cable must be disconnected.

Insert a suitable flathead screwdriver right into the recess of the locating latch, so that the latch releases the locating lug from the

plug.

Now you can pull out the connecting cable along with the flathead screwdriver.

dia. 45 and dia. 58

1.

2.

A

A = locating latch

8