Instruction Manual

– Model AFG Oil Burner

8

Burner packaged with appliance

•

Refer to appliance manufacturer’s wiring diagram for electrical connections.

Burner applied at jobsite

•

Refer to Figures 6 and 7, page 9, for typical burner wiring, showing cad cell

primary controls. Burner wiring may vary, depending on primary control ac-

tually used. The oil valve shown in Figures 6 and 7 may be an optional

feature.

All wiring must be in accordance with the latest revision of Na-

tional Electric Code

NFPA 70 and local codes and regulations.

The wiring diagrams in this manual are for

general reference only,

and apply only to burners equipped with R8184G or R7184 primary controls. For

other controls, refer to the control manufacturer’s literature or the diagrams sup-

plied with the appliance. Failure to apply correct wiring could result in severe

personal injury, death or substantial property damage.

The

R7184

primary control with valve-on delay (

prepurge) and

burner motor-off delay (

postpurge), shown in Figure 7, page 9, requires a con-

stant 120 VAC power source supplied to the

BLACK

wire on the control. The

RED

wire goes to the appliance limit circuit. Please note that other control

manufacturers may use different wire colors for power and limit connections.

Wire burner

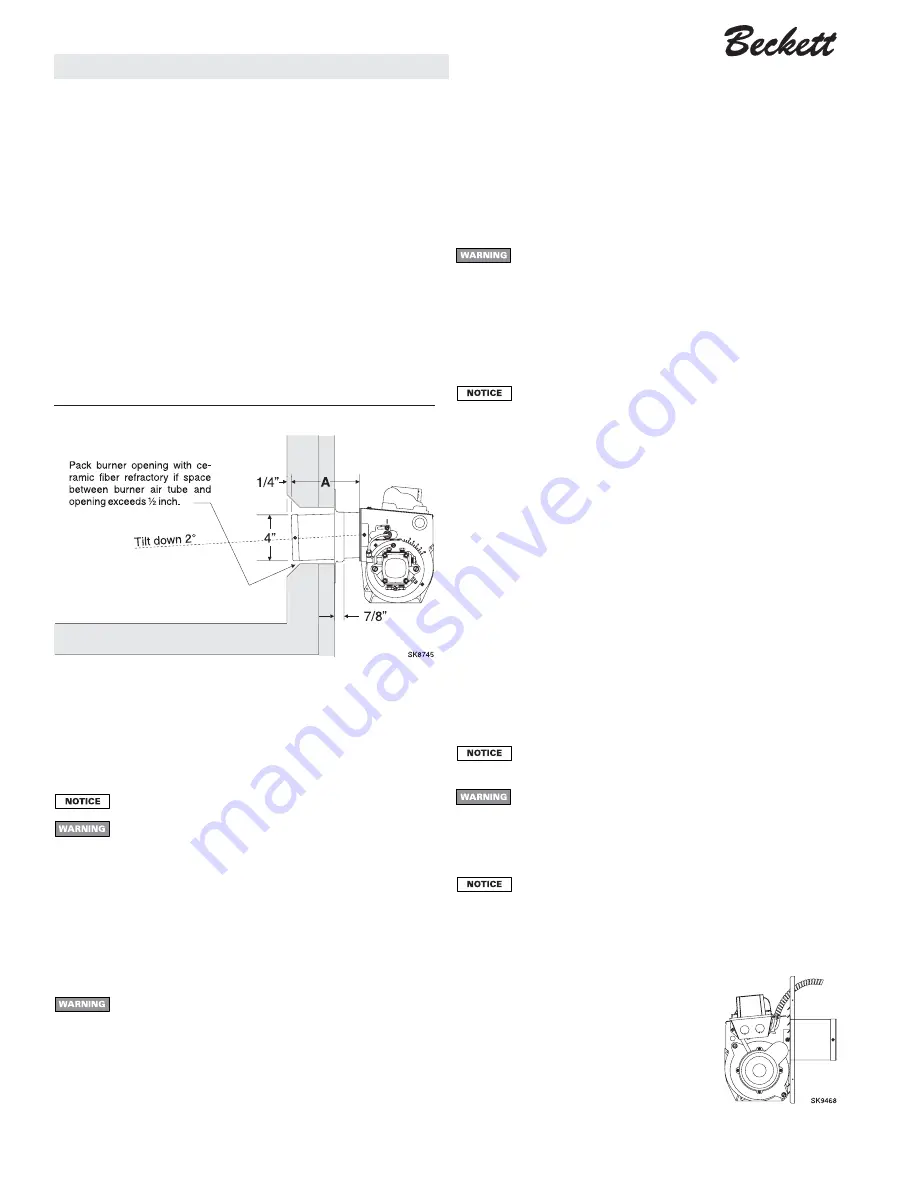

Figure 5

— Mounting burner in appliance

Mounting options

•

Bolt the burner to the appliance using the factory-mounted flange or an

adjustable flange.

Mounting dimensions

•

When using the Beckett universal adjustable flange, mount the air tube at a

2° downward pitch unless otherwise specified by the appliance manufac-

turer.

•

Verify that the air tube installed on the burner provides the correct insertion

depth. See Figure 5.

•

The end of the air tube should normally be ¼" back from the inside wall of

the combustion chamber. Never allow the leading edge of the head assem-

bly to extend into the chamber, unless otherwise specified by the heating

appliance manufacturer. Carefully measure the insertion depth when using

an adjustable flange. Verify the insertion depth when using a welded flange.

Mount burner on appliance

Connect fuel lines

Adjust, pipe & wire burner

Carefully follow the fuel unit manufacturer’s literature and the latest edition of

NFPA 31 for oil supply system specifications. If this information is unavailable,

use the following basic guidelines.

Fuel units with automatic bypass do not require a bypass plug.

The burner fuel unit is shipped without the bypass plug installed.

You must install this plug on two-pipe oil systems.

DO NOT

install the plug in

the fuel unit if connected to a one-pipe oil system. Failure to comply could cause

fuel unit seal failure, oil leakage and potential fire and injury hazard.

Fuel supply level with or above burner —

The burner may be equipped with a single-stage fuel unit for these installations.

Connect the fuel supply to the burner with a single supply line if you want a

one-pipe system (making sure the bypass plug is NOT installed in the fuel unit.)

Manual venting of the fuel unit is required on initial start-up. If connecting a

two-pipe fuel supply, install the fuel unit bypass plug.

The oil supply inlet pressure to the fuel unit cannot exceed 3 psi.

Install a pressure-limiting device in accordance with NFPA 31.

Fuel supply below the level of the burner —

When the fuel supply is below the level of the burner, a two-pipe fuel supply

system is required. Depending on the fuel line diameter and horizontal and

vertical length, the installation may also require a two-stage pump. Consult the

fuel unit manufacturer's literature for lift and vacuum capability.

Fuel line installation —

•

Continuous lengths of heavy wall copper tubing are recommended.

Always

use flare fittings. Never use compression fittings.

•

Always install fittings in accessible locations. Fuel lines should not run against

the appliance or the ceiling joists (to avoid vibration noise).

Never

use Teflon tape on any fuel fitting. Tape fragments can lodge

in fuel line components and fuel unit, damaging the equipment and preventing

proper operation.

Fuel line valve and filter —

•

Install two high quality

shutoff valves

in accessible locations on the oil

supply line. Locate one close to the tank and the other close to the burner,

upstream of the filter.

Some states require these valves to be fusible-handle design for

protection in the event of fire. We recommend this as good industry practice for

all installations.

•

Install a generous capacity

filter

inside the building between the fuel tank

shutoff valve and the burner, locating both the filter and the valve close to

the burner for ease of servicing. Filter should be rated for 50 microns or less.

Connect fuel lines

(continued)

Covered burners

The mounting plate is not a conduit connection

point. Pass conduit and attached connector

through the opening in the mounting plate (see

illustration at right) and attach it directly to the

burner-mounted 4x4 electrical box.

If attaching a burner cover to a previously in-

stalled burner, attach the mounting plate and

then slide the conduit into the "J" shaped con-

duit slot.