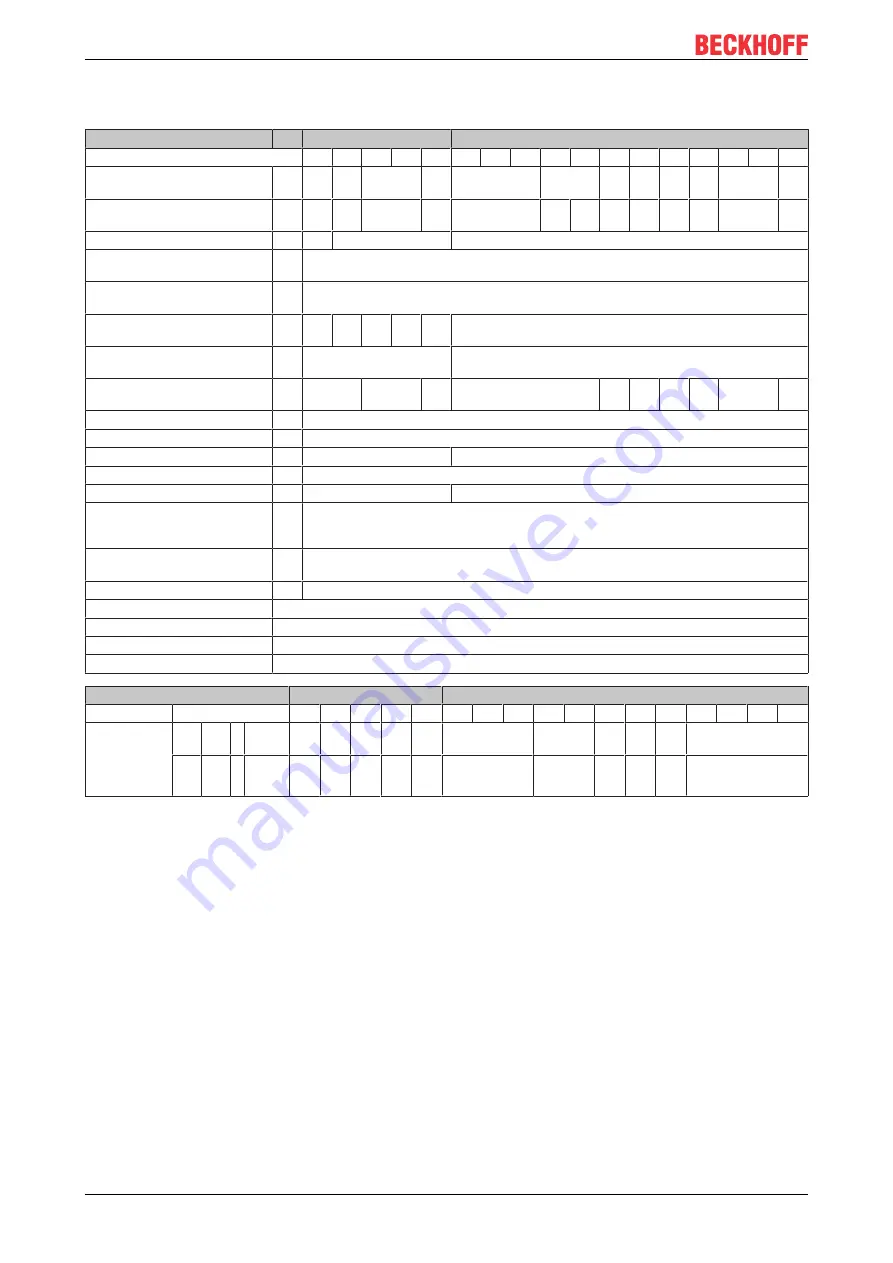

Technical data

Planetary gear unit LPxxx

24

Version: 1.6

8.3

LP090 MF 1 and MF 2

LP90

1-stage

2-stage

Ratio

3

4

5

7

10

9

12

15

16

20

25

30

35

40

50

70

100

Maximum acceleration torque

(max. 1000 cycles per hour) [T

2B

]

Nm 125 115

100

90

125

115

100 125 100 115

100

90

Nominal output torque

(at n

1N

) [T

2N

]

Nm

63

58

50

45

63

58

58

50

63

50

58

50

45

Emergency stop torque

1)

[T

2NOT

]

Nm 185

190

190

Nominal input speed [n

1N

]

min

-

1

3400

Max. continuous speed [n

1Max

]

min

-

1

6000

Average no-load running torque

2)

[T

012

]

Nm

0,6

0,6

0,5

0,4

0,4

0,3

Torsional backlash [j

T

]

(arcmin)

Standard < 8

Standard < 10

Torsional rigidity [C

t12

]

(arcmin)

12,0

9,5

8,5

12,0

9,5 12,0 9,5 12,0

9,5

8,5

Max. axial force

[F

2A

]

N

1900

Max. radial force

[F

2R

]

N

2400

Efficiency at full load

%

97

95

Service Life [L

h

]

h

> 20.000

Weight incl. adapter plate [m]

kg

4,0

5,0

Noise level

(At n1=3000 rpm without load)

[L

PA]

dB

< 66

Max. permissible housing

temperature

°C

+ 90

Ambient temperature

°C

- 15 to + 40

Lubrication

Lubricated for life

Paint

Grey RAL 7016

Direction of rotation

Motor and gearhead same direction

Type of protection

IP 64

LP90

1-stage

2-stage

Ratio

3

4

5

7

10

9

12

15

16

20

25

30

35

40

50

70

100

Mass moment

of inertia

3)

Clamping hub

diameter (mm)

G

24

J

1

kgcm²

1,9

1,7

1,6

1,5

1,4

1,5

1,6

1,5

1,4

1,5

1,4

H

28

J

1

kgcm²

2,2

2,0

1,9

1,8

1,7

1,8

1,9

1,8

1,7

1,8

1,7

1)

(Permissible 1000 times during the life span of the gear reducer)

2)

(at n1=3000 rpm and 20°C gearhead temperature )

3)

(referring to the drive)