7 Mechanical installation

Drive Technology

16 Version:

1.4

AM3100

7 Mechanical

installation

7.1 Important

notes

Attention

Destruction of the motors

•

Protect the motors from unacceptable stresses. Take care, especially during transport and

handling, that components are not bent and that insulation clearances are not altered.

•

The site must be free of conductive and aggressive material. For V3-mounting (shaft end

upwards), make sure that no liquids can enter the bearings.

If an encapsulated assembly is

required, please consult our applications department beforehand.

•

Ensure unhindered ventilation of the motors and observe the permissible ambient and flange

temperatures. For ambient temperatures above 40 °C please consult our applications

department beforehand.

•

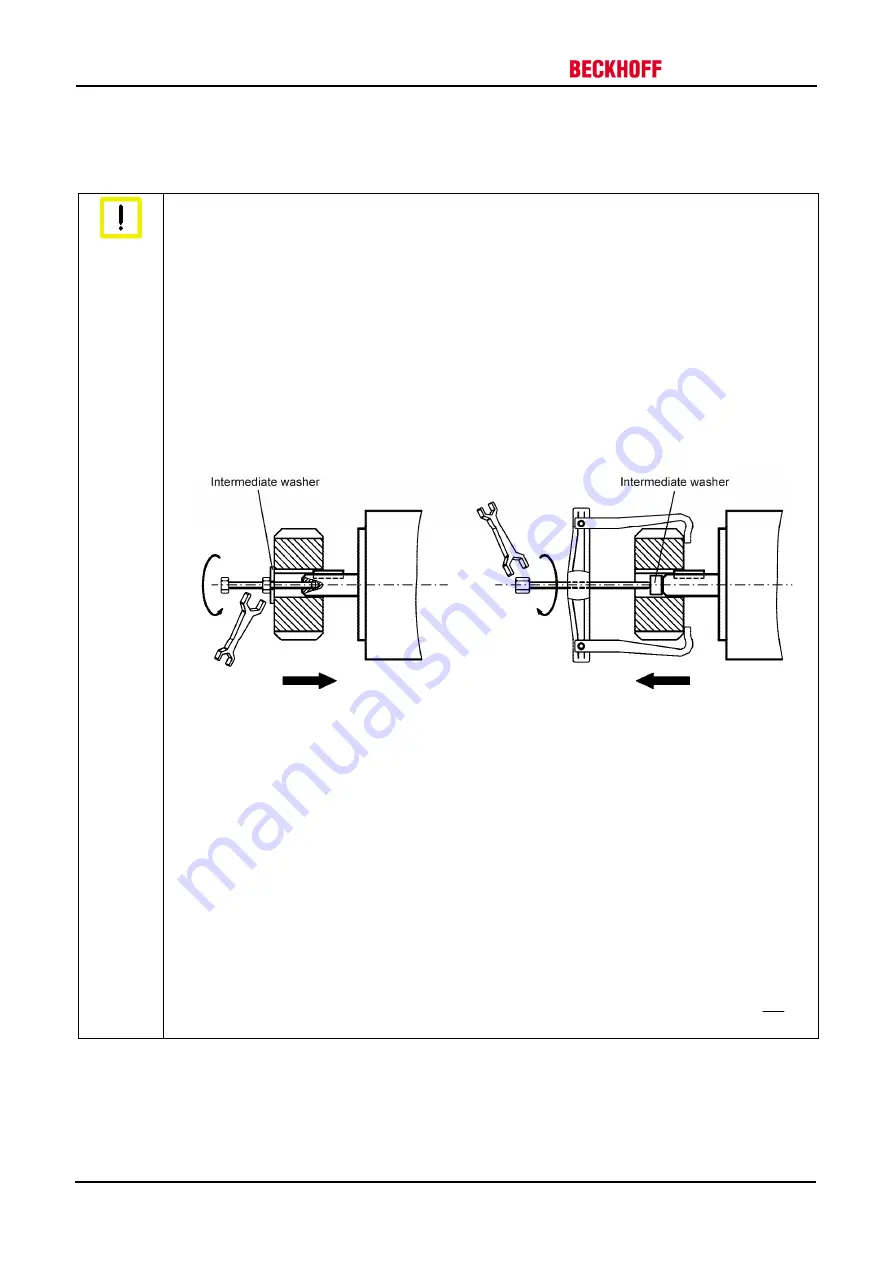

Servomotors are precision devices. The flange and shaft are especially vulnerable during

storage and assembly. It is important to use the locking thread which is provided to tighten

up couplings, gear wheels or pulleys and warm up the drive components, where possible.

Blows or the use of force will lead to damage to the ball bearings and the shaft.

•

Wherever possible, use only backlash-free, frictionally-locking collets or couplings.

Ensure

correct alignment of the couplings. A displacement will cause unacceptable vibration and the

destruction of the ball bearings and the coupling.

•

For toothed belts, it is vital to observe the permissible radial forces. An excessive radial load

on the shaft will significantly shorten the life of the motor.

•

Avoid axial loads on the motor shaft, as far as possible. Axial loading significantly shortens

the life of the motor.

•

In any case, avoid creating a mechanically constrained motor shaft mounting by using a rigid

coupling with additional external bearings (e.g. in a gearbox).

•

Take note of the no. of motor poles and the no. of resolver poles and ensure that the correct

setting is made in the used servo drives. An incorrect setting can lead to the destruction of

the motor, especially with small motors.

•

Check compliance the permitted radial and axial loads F

R

and F

A

. When using a toothed belt

drive, the

minimum

permitted diameter of the pinion follows from the equation:

2

0

min

x

F

M

d

R

≥