Product overview

Version: 4.3

───

23

AM8000 and AM8500

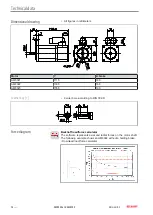

3.4.4

Sealing air connection

3.4.4

Ingress of fluids or dust at different temperature ranges can be pre-

vented by a separate sealing air connection with a defined overpres-

sure. The overpressure is achieved by connection to a regulated

compressed air system. It is installed together with an axial shaft

sealing ring.

A sealing air connection is recommended for:

• Critical installation locations with extreme dust exposure

• Motors with permanent and direct fluid contact

Important

In the horizontal mounting position IM V3, liquid can accumulate

permanently on the motor flange and penetrate into the motor. Even

a sealing air connection cannot completely prevent the liquid from

entering.

An air hose provided by the customer must be connected to a suit-

able regulated pressure reducer. The compressed air must be free

of oil and dust.

Minimum requirements and technical data:

Compressed air re-

quirement

according to DIN ISO 8573-1 Class 3:2010

[A:B:C]

Operating pressure

0.1 ± 0.05 bar

Maximum pressure

0.3 bar

Air connection

Quick-release coupling

Required air line

e.g. PA hose 6 mm x 4 mm

Summary of Contents for AM8000 Series

Page 1: ...Operation Instructions EN AM8000 and AM8500 Synchronous Servomotors 8 27 2020 Version 4 3 ...

Page 2: ......

Page 122: ......