Appendix

22

BK8000

Appendix

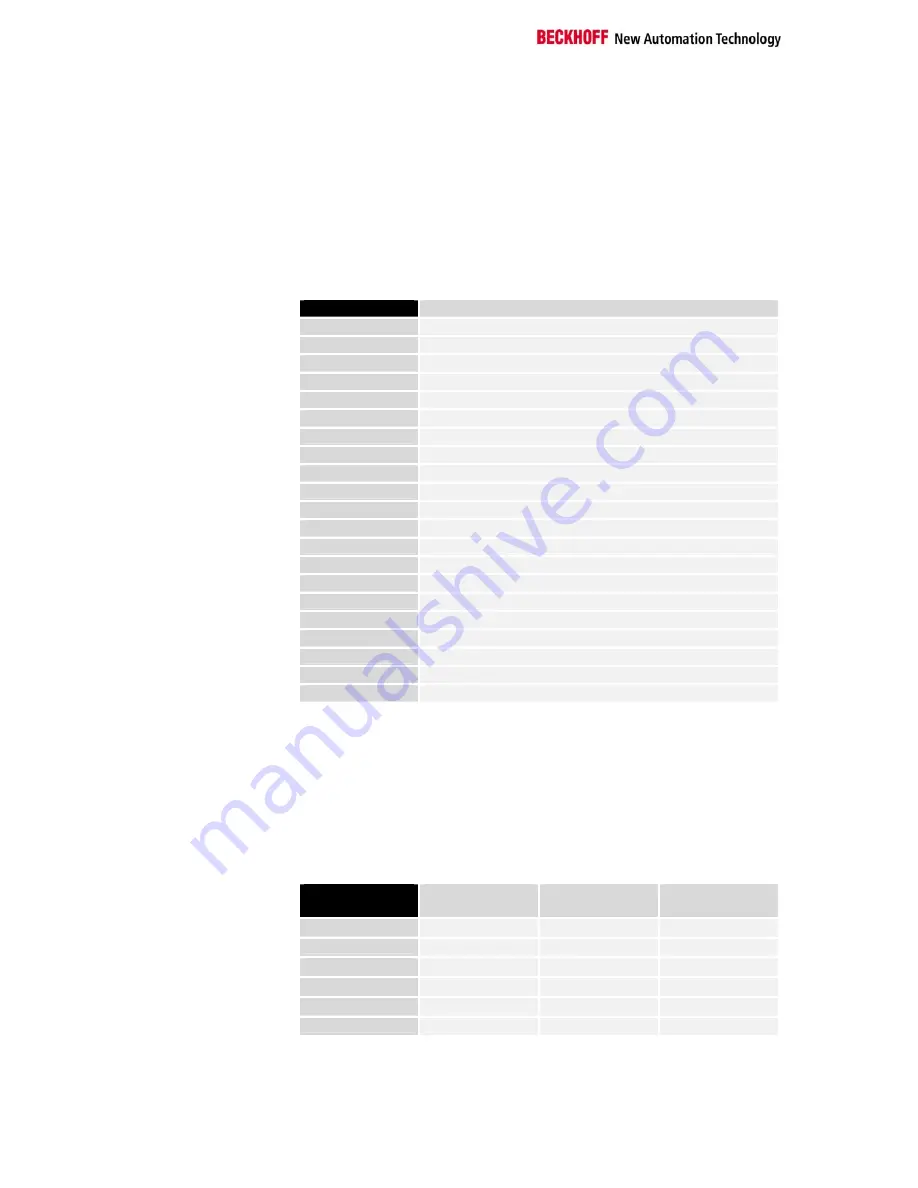

Sample arrangement of a process image in

the bus coupler

The following example will illustrate the assignment of input/output

channels to the process image. Our sample construction is to consist of the

following bus terminal components:

For this configuration

Position

Function component on the track

the bus coupler will create

POS01

Bus coupler

the list of assignments

POS02

2-channel digital input

shown below

POS03

2-channel digital input

POS04

2-channel digital input

POS05

2-channel digital input

POS06

2-channel digital input

POS07

2-channel digital output

POS08

2-channel digital output

POS09

2-channel digital output

POS10

2-channel analog input

POS11

2-channel analog output

POS12

2-channel analog output

POS13

2-channel analog input

POS14

Power input terminal

POS15

2-channel digital input

POS16

2-channel digital input

POS17

2-channel digital input

POS18

2-channel digital output

POS19

2-channel digital output

POS20

2-channel analog output

POS21

End terminal

In the default settings, RS485, RS232, CANopen, DevicNet, InterBus and

Profibus couplers only map the analog input/output terminals in 16-bit wide

signal channels. The CONTROL/STATUS byte is not available. That is to

say, an analog terminal with two channels, for example, appears with two

times 16 bits in the process image. The PLC interface is not integrated in

the process image. Accordingly, the byte address and allocation mappings

present themselves differently when CONTROL/STATUS is activated. For

the function and system terminals, refer to the terminals' configuration

instructions for details of the mapping in the bus coupler process image.

Area for byte-oriented

data, analog outputs

Relative byte

address

Bit position

Process image in

the control unit

Position in the

block

0, 1

none

O0, O1

POS11

2, 3

none

O2, O3

POS11

4, 5

none

O4, O5

POS12

6, 7,

none

O6, O7

POS12

8, 9

none

O8, O9

POS20

10, 11

none

O10, O11

POS20