Commissioning

EL33xx-00x0

136

Version: 4.2

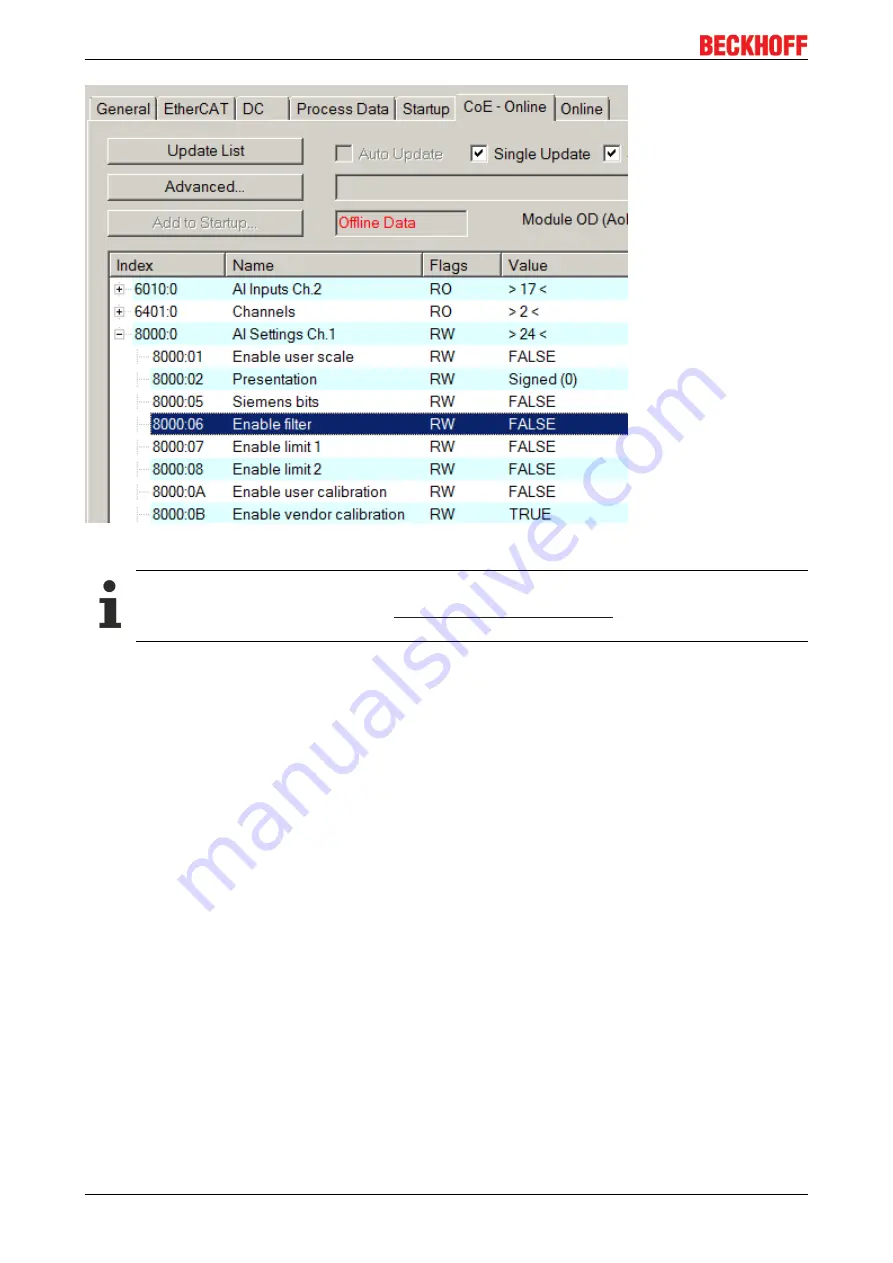

Fig. 153: EL3102, CoE directory

EtherCAT System Documentation

The comprehensive description in the

(EtherCAT Basics --> CoE

Interface) must be observed!

A few brief extracts:

• Whether changes in the online directory are saved locally in the slave depends on the device. EL

terminals (except the EL66xx) are able to save in this way.

• The user must manage the changes to the StartUp list.

Commissioning aid in the TwinCAT System Manager

Commissioning interfaces are being introduced as part of an ongoing process for EL/EP EtherCAT devices.

These are available in TwinCAT System Managers from TwinCAT 2.11R2 and above. They are integrated

into the System Manager through appropriately extended ESI configuration files.

Summary of Contents for EL33-00 Series

Page 2: ......

Page 6: ...Table of contents EL33xx 00x0 6 Version 4 2...

Page 17: ...Product overview EL33xx 00x0 17 Version 4 2 Fig 10 EL3312 Fig 11 EL3314...

Page 18: ...Product overview EL33xx 00x0 18 Version 4 2 Fig 12 EL3314 0002 Fig 13 EL3314 0010...

Page 61: ...Mounting and wiring EL33xx 00x0 61 Version 4 2 Fig 45 EL3314 0010 Fig 46 EL3314 0090...