Commissioning

EL6692

126

Version: 3.2

TwinCAT can now be activated and started on this side. All devices must be in OP, WorkingCounter = 0, no

LostFrames. The EL6692 time stamps on the PrimarySide remain at 0, because the SecondarySide has not

yet been configured.

Sync Slave side

The EL6692,

SecondarySide

is set to DC and 0x1A02 according to the fig.

Set the EL6692 PrimarySide to

DC

and

Activate PDO 0x1A02 to display the time stamp.

After reloading the configuration (or restarting in

ConfigMode

, FreeRun), the synchronization direction can be

read out by means of

GetConfiguration

on the

SecondarySide

, see the fig.

SecondarySide of the EL6692

.

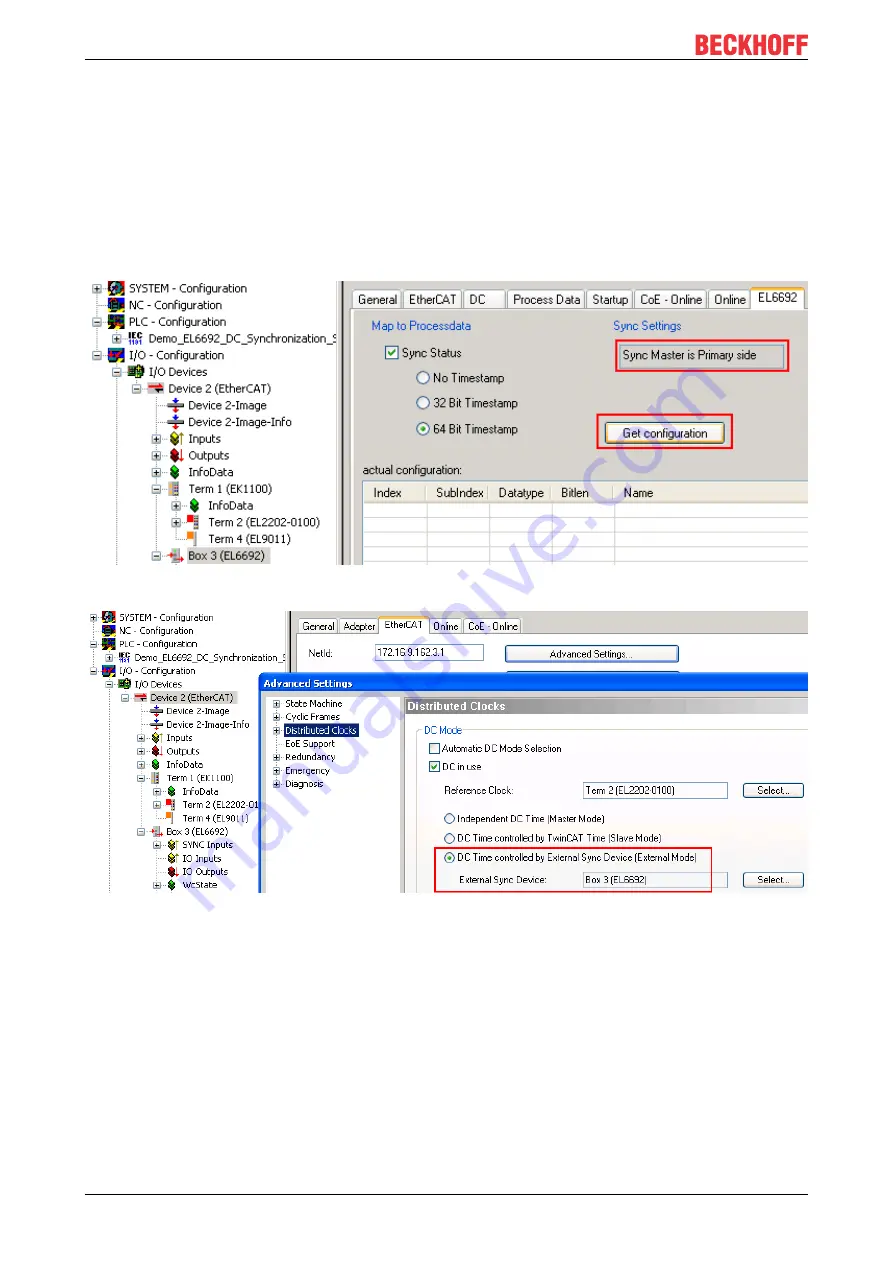

Fig. 165: SecondarySide of the EL6692

Fig. 166: EtherCAT master settings, slave side

After the restart, the DC function of the EL6692 is known to the EtherCAT master; therefore, it now offers this

EL6692 as an

ExternalSyncDevice

in the DC dialogue.

The linking of the following variables is necessary for the evaluations; see the fig.

Slave side.