Chapter 1

Bedrock SPS.500 Overview

6

Bedrock SPS.500 User Manual - BRDOC125_007

9/3/21

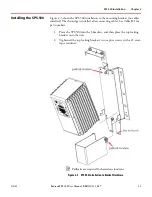

SPS.500 in a parallel configuration with an UPS.500. This is the preferred

configuration for wiring an SPS.500 with an UPS.500.

Figure 1

-

5 SPS.500 Parallel Wiring Diagram with UPS.500

One of the

following:

x

Workstation

Running

OPC UA

x

Bedrock

SIO4.E comm.

module

x

UCG.5

x

OSA Remote

Load

Recommended

Fusing

Power

Out

Power

In

Recommended

Fusing

To Discrete

Inputs for

Alarming

Relay

Output

(optional)

Ethernet

Battery

Enable

Connector

Ethernet

ORed

Output

Power

Out

SPS.500

UPS.500