13. Unauthorized modifications to the machine may impair the function and/or safety of

the machine and reduce its life. If equipment has been altered in any way from

original design, the manufacturer does not accept any liability for injury or warranty.

4.02 - Service

Before each use:

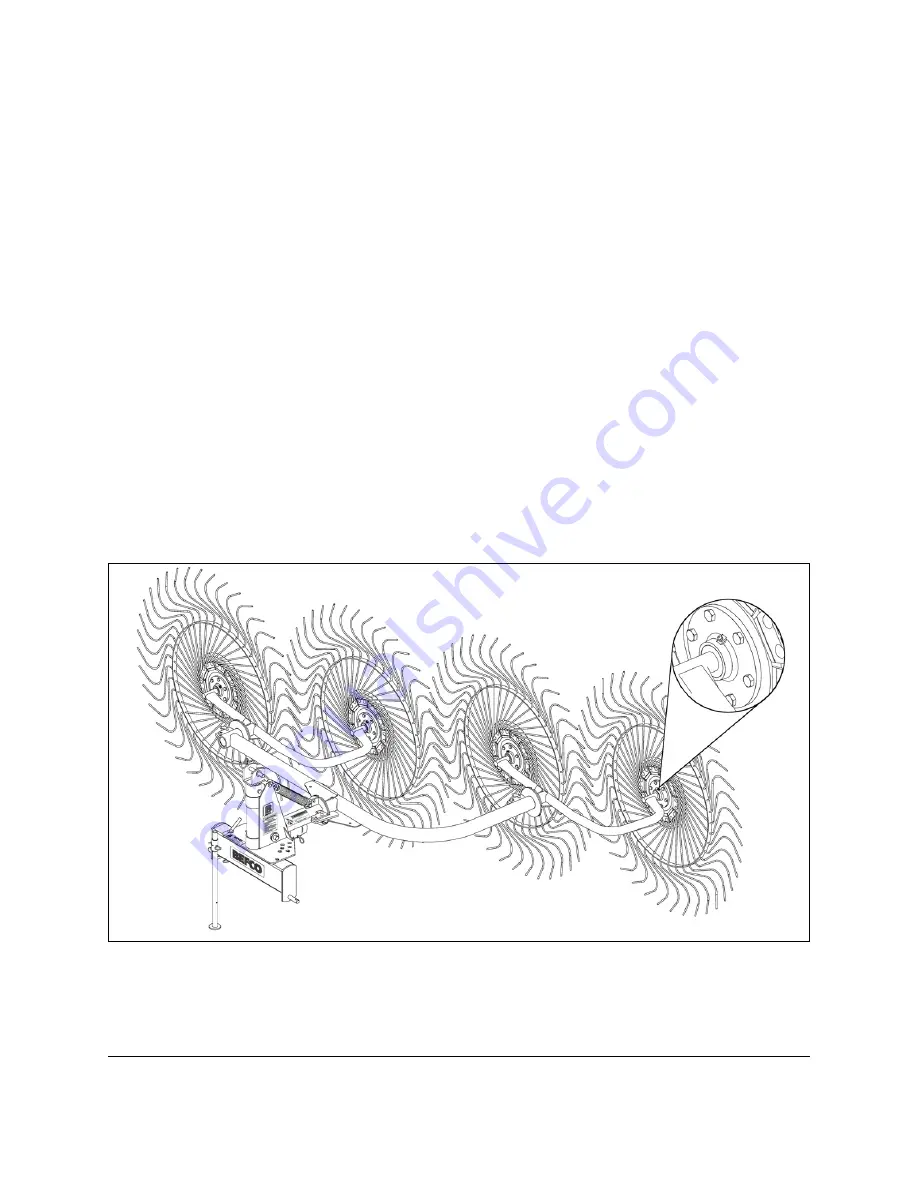

1. Check machine condition, particularly the rake wheels. Check for any loose teeth,

bolts or missing hardware.

2. Replace any damaged or worn tooth.

Hourly or whenever an obstacle is hit:

1. Check machine condition, particularly the rake wheel teeth.

2. Replace any damaged or worn tooth.

3. Remove any wrapping (stalks, weeds, trash, etc.) from implement.

Every 8 hours:

Grease fittings on wheel hubs

(see fig. 12)

.

Every 25 hours:

Check hardware tightness;

vibration can loosen bolts

7

.

M

AINTENANCE

22

BEFCO

H

AY

R

AKES

O

PERATOR

’

S

M

ANUAL

7

Refer to Table 1 - Torque Specifications, page 23.

Fig. 12 - Grease points

Summary of Contents for RS2-04L

Page 36: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 04 PARTS MANUAL 36 BEFCO 08 2013...

Page 38: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 05 PARTS MANUAL 38 BEFCO 08 2013...

Page 40: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 06 PARTS MANUAL 40 BEFCO 12 2013...

Page 44: ...HAY RAKES DECALS OPERATOR S MANUAL RS2 04 RS2 05 RS2 06 PARTS MANUAL 44 BEFCO 08 2013...

Page 46: ......