6 - TROUBLESHOOTING

WARNING: Be sure tractor engine is off, parking brake is locked, and key is

removed before making any adjustments.

Ensure tractor SCV lever is in float

position while working.

Bolt lower spring clip to hole further

away from springs to reduce ground

pressure

(see fig. 5)

.

Excessive ground pressure.

Replace bearing.

Bearing failure.

Grease rake wheel.

Insufficient lubrication.

Individual wheel is

not turning.

Run at an angle to the hay or early

in the morning when hay is damp.

Very light, fluffy hay, hay

getting caught in wheel

supports.

Adjust top link.

Wheels are stalling.

Increase or decrease ground speed.

Incorrect ground speed.

Hay bunching.

Ensure tractor SCV lever is in float

position while working.

Bolt lower spring clip to hole further

away from springs to reduce ground

pressure

(see fig. 5)

.

Excessive ground pressure.

Lower three point hitch.

Rake wheels bounce

excessively.

Replace teeth so all are same

length.

Teeth missing or heavily

worn.

Increase pitch by lengthening top

link.

Raking wheel not pitched

back.

Adjust angle of rake

(see fig. 6)

.

Rake wheel turning too

straight.

Adjust rake wheels lower to ground.

Rake wheels too high.

Rake missing hay.

Shorten top link so teeth do not run

so heavy on the ground.

Mud on teeth ends.

Allow hay to dry.

Wet hay.

Run rake wheels on gravel road for

a short distance.

New teeth.

Wheel does not

unload hay.

SOLUTION

POSSIBLE CAUSE

PROBLEM

T

ROUBLESHOOTING

26

BEFCO

H

AY

R

AKES

O

PERATOR

’

S

M

ANUAL

Summary of Contents for RS2-04L

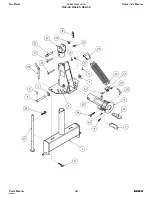

Page 36: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 04 PARTS MANUAL 36 BEFCO 08 2013...

Page 38: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 05 PARTS MANUAL 38 BEFCO 08 2013...

Page 40: ...HAY RAKES FRAME OPERATOR S MANUAL RS2 06 PARTS MANUAL 40 BEFCO 12 2013...

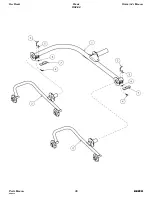

Page 44: ...HAY RAKES DECALS OPERATOR S MANUAL RS2 04 RS2 05 RS2 06 PARTS MANUAL 44 BEFCO 08 2013...

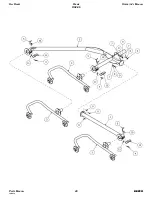

Page 46: ......