English

⋅

Fornax

®

T

19

A

-en

en

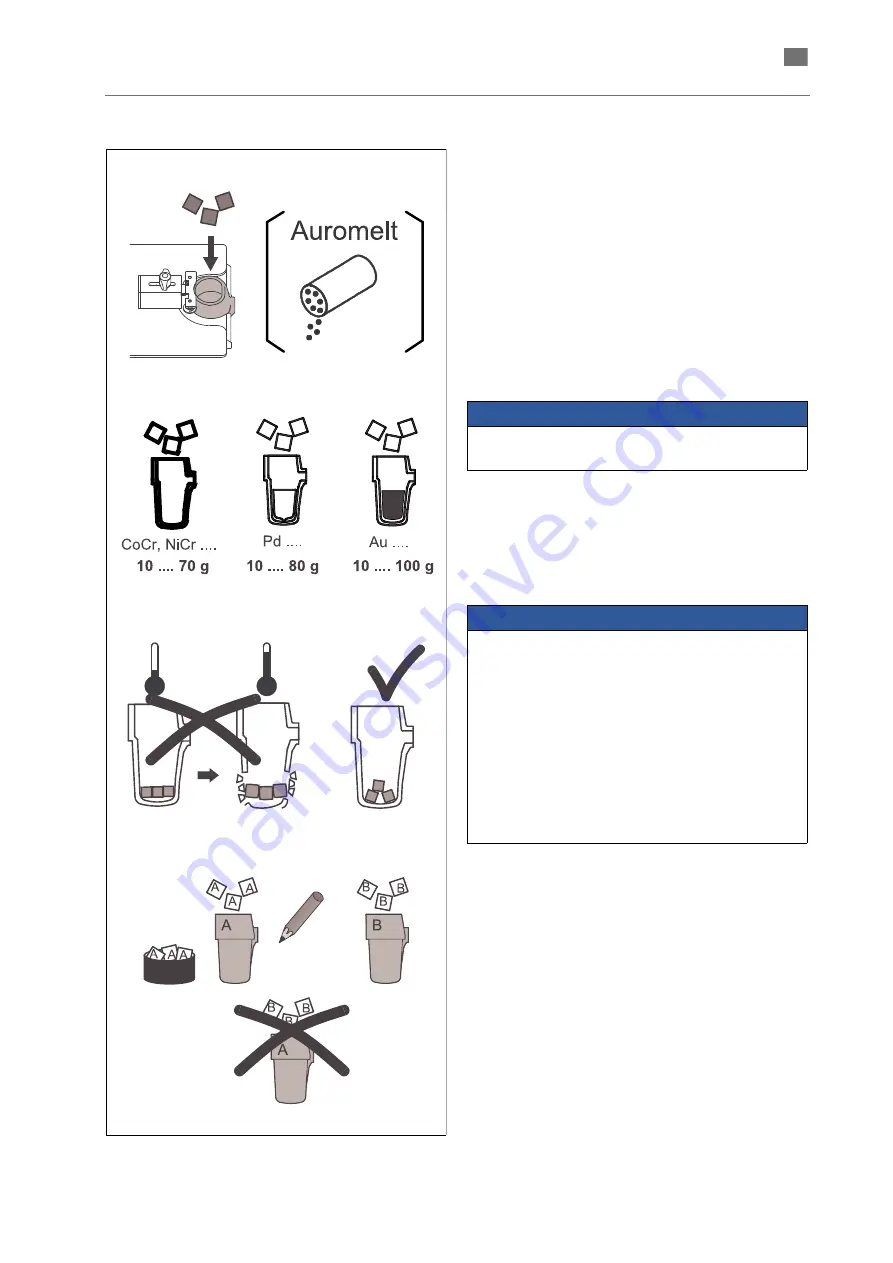

Filling the crucible

1.

Fill the desired alloy into the clamped crucible.

2.

In the case of special alloys, sprinkle a pinch of

BEGO Auromelt HF melting powder on the

alloy (see table on page 26).

Melting powder made by other manufacturers

may impair the casting result!!

Auromelt HF should be used very sparingly

(only a pinch)!

3.

Depending on the selected alloy, place an

additional graphite insert (REF 52454), glassy

carbon insert (REF 54883) or ceramic insert

(REF 52455) into the ceramic crucible during

the melting process (see casting table

page 26)!

Pile alloy plates loosely into the ceramic crucible as

it may otherwise crack during heating!

Recommendation: Fill in old metal first, top off with

new metal.

Always use crucible and inserts for the same alloy.

Crucibles can be written on with a pencil.

NOTICE

ATTENTION!

• Observe minimum and maximum quantities!

NOTICE

Alloys with a high palladium content are generally

casted in a ceramic insert. A glassy carbon insert

can be used if the alloy chips rise during the

heating process and thus do not have the proper

temperature (failed "incorporation" in the

induction field):

• with palladium contents up to 30% of the graph-

ite insert,

• with palladium contents over 30% of the glassy

carbon insert, which reliably prevents carbon

from being absorbed by the alloy.