English

⋅

Fornax

®

T

21

A

-en

en

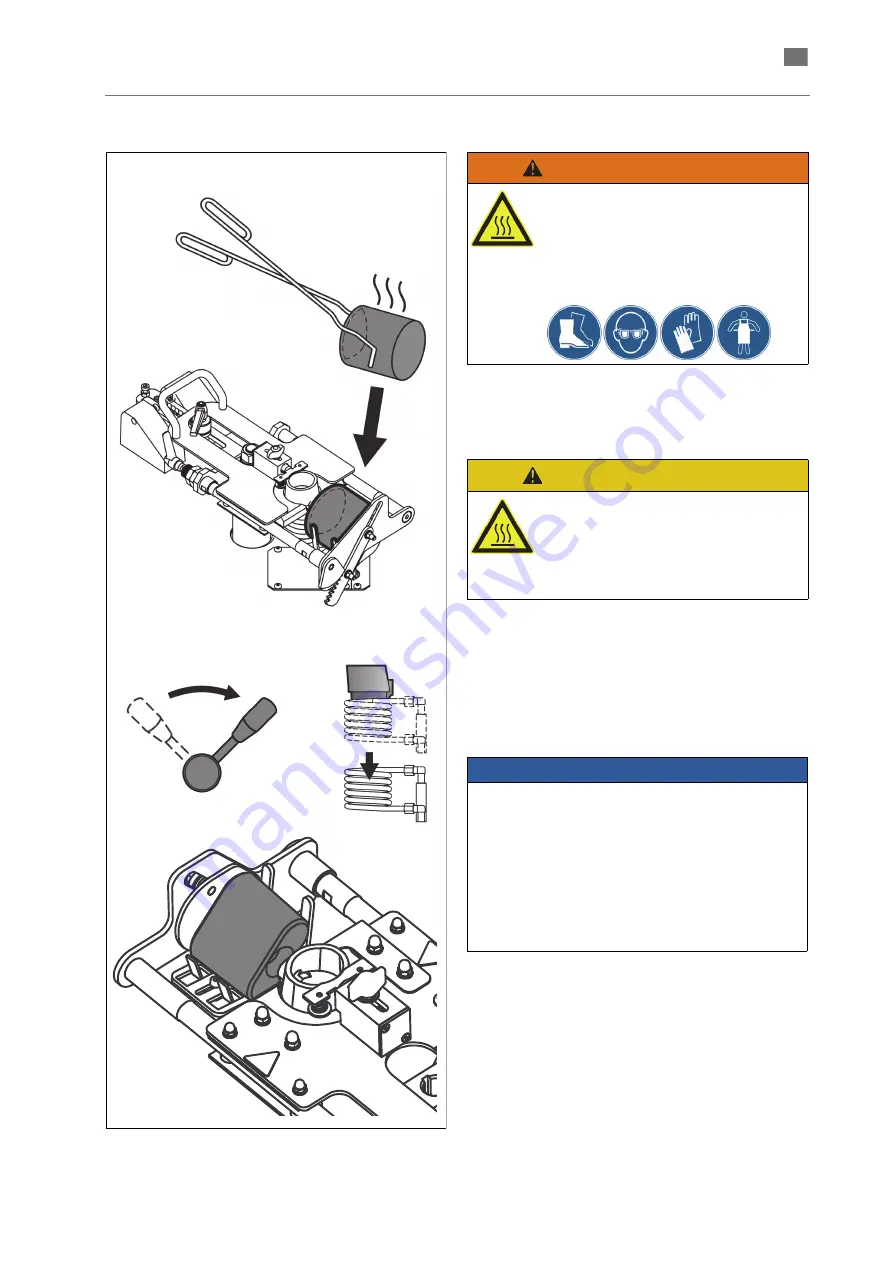

Insert mould

1.

Insert the preheated mould into the mould

holder. The mouth of the ingot mould must

face the crucible.

2.

Lower the crucible coil to adjust the mould dis-

tance. Push the handle located on the right

exterior side of the device backward for this

purpose.

3.

Oval moulds (see image) may be inserted as

well. For this purpose, the angle of the crucible

holder can be adjusted individually by loosen-

ing and/or tightening the mounting screws.

WARNING

Burn hazard from hot parts!

• Always use mould tongs to move

moulds.

• Wear suitable protective equipment

when operating the device!

CAUTION

Mould temperatures above

1050°C may cause the device to

overheat.

Never use damaged or cracked

moulds.

NOTICE

Ideally, the setup should be carried out with a cold

mould before it is placed into the preheating

oven. A "dummy" may be used alternatively.

A setup with a hot mould is required if the

presetting did not take place or if the model

casting moulds have different shapes, for

instance if they are imbedded with crepe sleeves.

(here, moulds may have different heights and

diameters)