English

⋅

Nautilus

®

CC plus

⋅

Nautilus

®

T

23

A

en

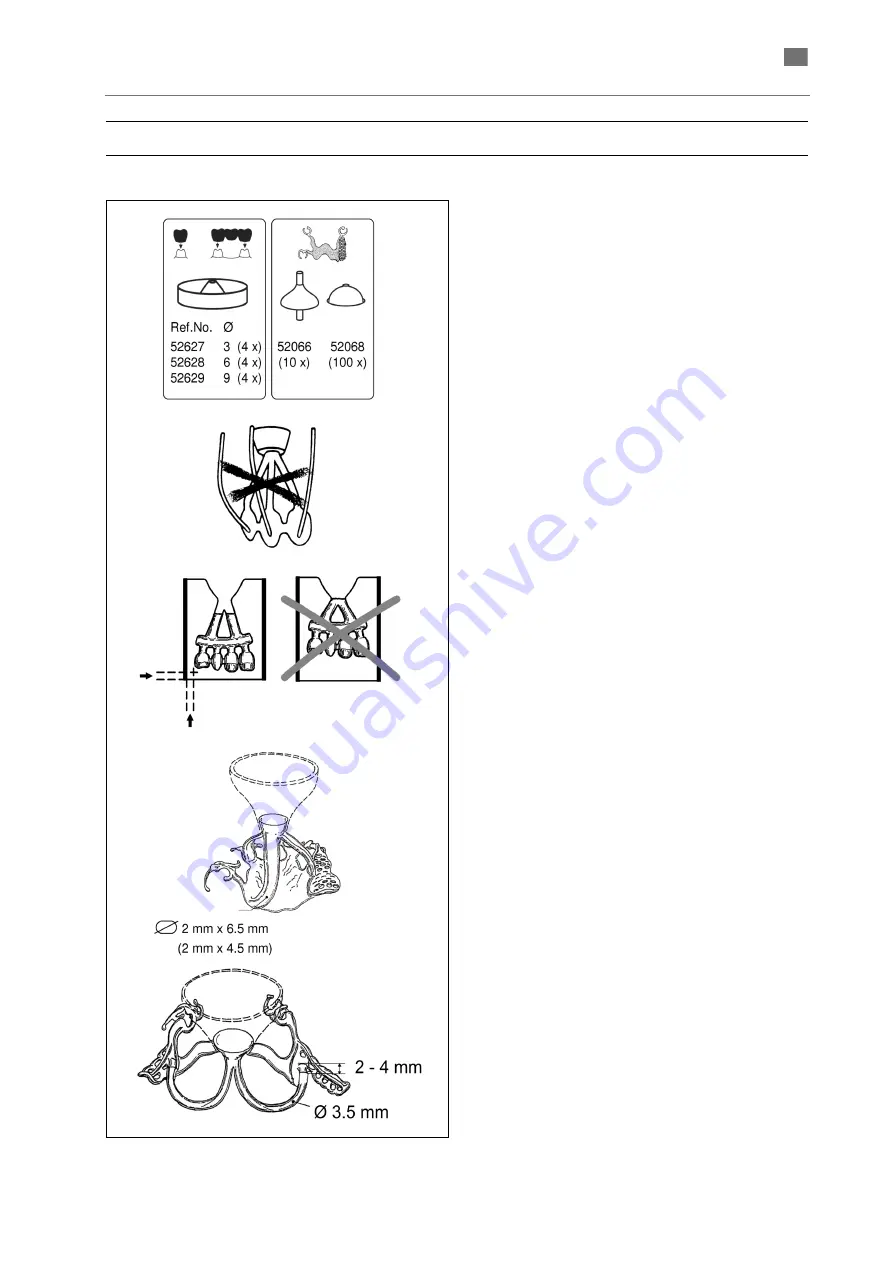

Basic principles: Wax-up

After the crucible is opened, the melt flows into the

mould by gravity and immediately fills the sprues.

With the aid of compressed air, the entire mould

cavity is then instantaneously filled with hot melt.

The object should first harden and must be able to

suck liquid melt from the reservoir of the sprues. The

following rules must be strictly observed for this

purpose.

BEGO casting mould formers are specially

designed for the flow of melt from NAUTILUS

®

crucibles and should therefore be used.

Do not use vent sprues that reach up to the

casting funnel or to the outside of the mould. Air

vents cause the compressed air to be supplied

incorrectly during the pressing process.

The object should first harden and enable subse-

quent suction of the liquid melt from the heat centre

of the mould.

For this reason, keep a small gap (5 mm) between

the object and the mould base and mould wall.

Arrange bridges in a ring shape at the mould wall.

Partial denture

Follow the illustrations and the instructions of the

alloy manufacturer when dimensioning the sprues.

Summary of Contents for 39701001

Page 1: ...Gerätedokumentation Miteinander zum Erfolg ...

Page 2: ......

Page 4: ......

Page 11: ...English Nautilus CC plus Nautilus T 7 86105 BA en 01 en Unpacking Packing REF 17909 ...

Page 47: ...Nautilus CC plus en English ...

Page 63: ...Nautilus T en English ...

Page 87: ...English Nautilus CC plus Nautilus T 83 86105 BA en 01 en NAUTILUS T bar ...

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......