26

A

English

⋅

Nautilus

®

CC plus

⋅

Nautilus

®

T

en

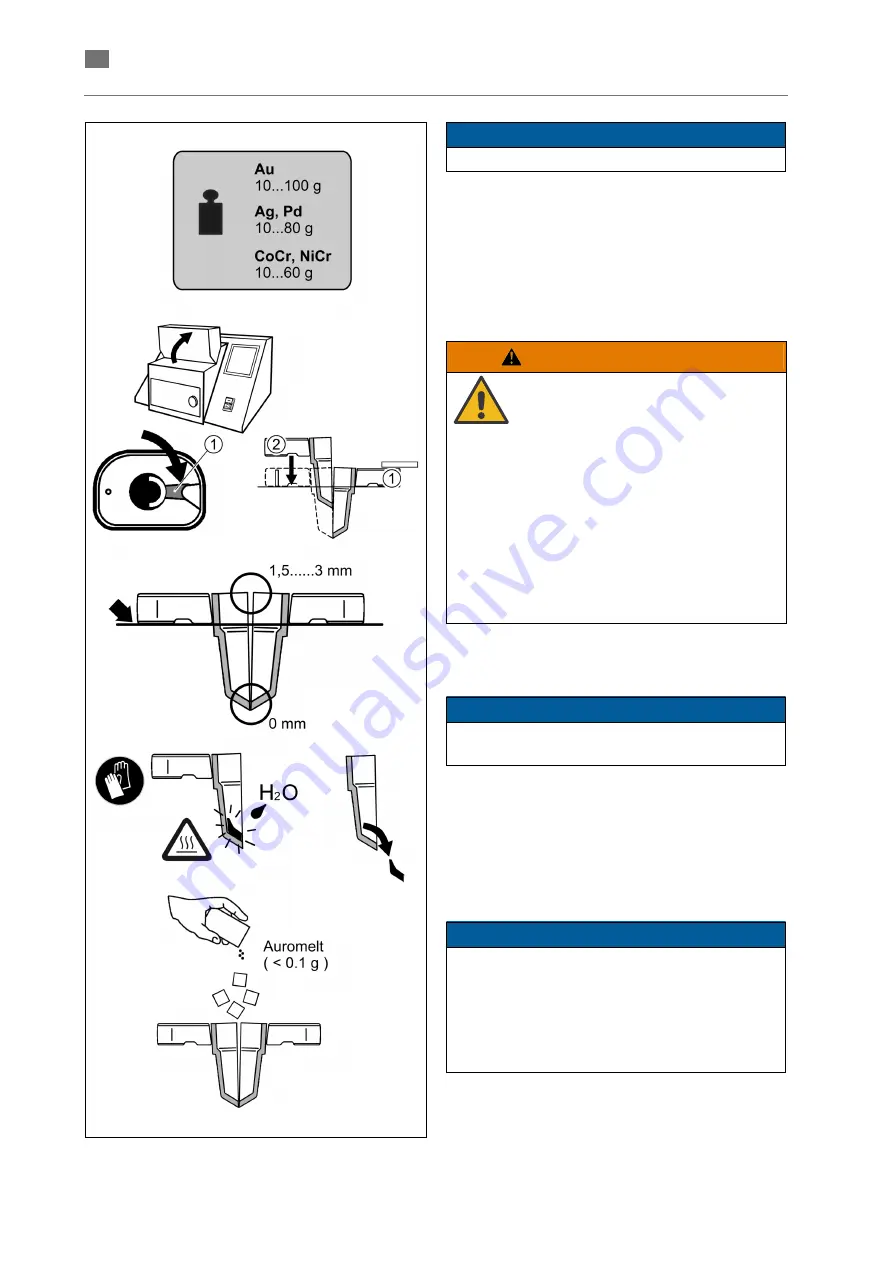

Insert both crucible halves.

(*): Uneven crucible tips that do not close can be

smoothed out by pulling them over fine sandpaper

(grit size

≥

80).

With special alloys, sprinkle a pinch of BEGO

Auromelt HF melting powder on the alloy (see

program table on page 34).

Melting powder made by other manufacturers may

impair the casting result!

(**) Crucible halves can "stick" to each other due to

an excessively large amount of flux, which can

result in a delayed crucible opening.

NOTE

Observe minimum and maximum quantities!

WARNINGS

ATTENTION (check before every

casting process)

• The handles must lie on the base

surface.

• The crucible halves must close/seal

on the bottom (*) and leave a gap

between 1.5 to 3 mm at the top.

• Do not use damaged crucible

halves.

• CoCr / NiCr only: do not use crucible

halves with alloy residue on the bot-

tom.

NOTE

Alloy residues can be easily removed if a drop of

water is added while they are hot.

NOTE

Glazing the inside of the crucible is not recom-

mended!

The crucible halves can "stick" to each other due

to the glaze layer, which can result in a delayed

crucible opening and consequently a faulty

casting.

Summary of Contents for 39701001

Page 1: ...Gerätedokumentation Miteinander zum Erfolg ...

Page 2: ......

Page 4: ......

Page 11: ...English Nautilus CC plus Nautilus T 7 86105 BA en 01 en Unpacking Packing REF 17909 ...

Page 47: ...Nautilus CC plus en English ...

Page 63: ...Nautilus T en English ...

Page 87: ...English Nautilus CC plus Nautilus T 83 86105 BA en 01 en NAUTILUS T bar ...

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......