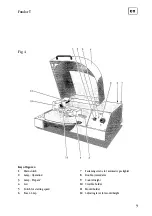

Fundor T

6

The Fundor T is a benchtop machine for casting dental

work. It can be used for precious metal, cobalt-crome

and metal-to-ceramik alloys or no precious metal

content.

The ingots are melted with a flame. We recommend to

use for melting only the

Multiplex

melting torch for

propane/natural gas/oxygen and for simplifying the

setting of the flame the

automatic gas lighter

.

Height

260 mm

Height with lid raised

850 mm

Width

770 mm

Depth

650 mm

Weight

45 kg

Rated voltage

200 .... 240 V, 50/60 Hz

Special voltage

100 .... 120 V, 50/60 Hz

Power consumption

600 W

Speed

about 500 min

-1

Noise emission

< 70 dB (A)

Ambient temperature (max.)

40 °C

Instructions according to the centrifuge regulation (Germany):

Mode of operation S3 10% (intermittent service with

10% continous duty)

Max. centrifuge quantity 1 kg (mould, crucible, alloy)

Kinetic energiy

about 300 Nm

Technical data

Unit description

Scope of delivery

Fundor T with double-jointed arm

200 .... 240 V, 50/60 Hz ________ Order-No. 25025

100 .... 120 V, 50/60 Hz ________ Order-No. 25026

with: • 1 pack Auromelt HF melting powder

• 1 pair of safety goggles

• 2 feet accepting screw

• 3 crucibles for precious metal alloys

• 3 crucibles for cobalt-chrome and non-

precious metal alloys

• 2 replacement tension springs for the

centrifugal arm

• 2 replacement fuses 4 amp.

• 1 replacement fuses 0,1 amp. (for PCB)

Scope of delivery, Wearing parts and Extras

Wearing parts

• Crucibles for precious metal alloys

(1 pack = 6 pcs) __________ Order-No. 52425

• Crucibles for cobalt-chrome and non-precious

metal alloys (1 pack = 6 pcs) _ Order-No. 52426

• Tension spring for centrifugal arm

1 pcs ___________________ Order-No. 34924

Extras

• Multiplex Microflame soldering and melting torch

for natural-gas/oxygen or propane/oxygen

______________________ Order-No. 25385

• Automatic gas lighter ________ Order-No. 34958

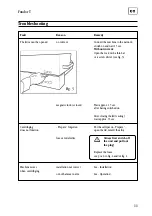

Centrifuging is started by closing the lid. The double-

jointed arm optimises the centrifugal force. The

starting speed is infinitely variable.