Fundor T

7

Installation

Only a trained worker is allowed to install

the Fundor T.

Observe the safety information!

l

Place the Fundor T on a level worktop. Fundor T

has to contact the working bench with all four feet.

The front right rubber foot can be used for levelling

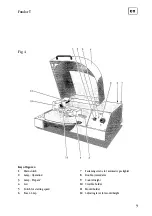

- after opening side panel (see figure 1).

l

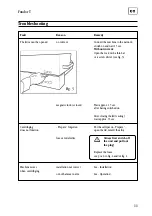

There is the possibility to screw on two feet. Open

the right-hand side panel and unscrew the two

rubber feet. Fasten the separately delivered feet and

mark the fixing points at the bench. Drill holes in

the worktop and screw the casting machine down

with suitable screw (see figure 2).

l

Install the

Multiplex melting torch

next to the

machine in a suitable position.The

automatic

gas lighter

facilities enormously the firing and

adjustingof the melting torch. It can be mounted at

the wall or at the back of Fundor T (pos. 7 in fig. 4).

When installing these units take notice of their

instructions for use.

Fig. 1

Fig. 2