Fundor T

8

Working

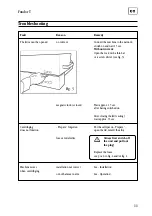

Danger of burns due to hot parts!

l

Wear protective clothing (protective apron), safety shoes, safety goggles and protective gloves.

l

Always use mould tongs to move moulds and hot crucibles.

l

Place hot parts only on a fireproof surface.

The counterweight of the mould ist to be correctly adjusted in the clicking points in order

to prevent the out-of-balace and so a moving of the machine when centrifugal casting.

1.

Switch main switch

1

on („I“): green LED

2

will come on.

2.

Lid

4

of the centrifuging chamber may be opened after about 15 seconds.

3.

Set the starting sped required at switch

5

scale mark 4 for precious metal alloys for crown and bridges,

scale mark 6 for precious metal alloys for metal-ceramics,

scale mark 8 for alloys based on palladium,

scale mark 8 for cobalt-chrome and nickel-chrome alloys.

These are guide values. Infinitely variable adjustment makes other values possible. The

optimal starting speed depends on the composition of the alloy, the temperature and the flow

properties of the melt. Lower starting speed values may also be favourable for some alloys.

4.

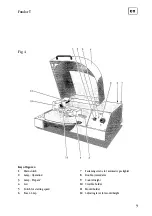

Turn the double-jointed arm

8

counter-clockwise so that the counterweight

9

stands at the right (fig. 4).

5.

Set the counterweight for the size of mould being used by raising the weight, movingit and engaging it

securely again. Example: for amould of size

3

approach the counterweight to the figure 3.

If the counterweight is not se correctly, the out-of-balace of the centrifugal armmay move the

machine.

6.

Put crucible in its holder

10

and put casting metal in. Use for cobalt-chrome alloys and non-precious alloys

low crucibles (Order-No. 52426) and put the casting cylinderside bei side.

7.

Put the mould on the mould holder

11

and adjust the height at lever

12

so that casting funnel and crucible

opening align.

8.

Push the crucible on the mould.

9.

Switch main switch to „Prepare” ( ) symbol (switch springs back to „I“): the yellow LED

3

flashs. The

machine ist now ready for casting.

10. Ignite the Multiplex melting torch, adjust it and melt the casting metal. NB: Please observe Operating

Instructions for Multiplex.

11. Close the lid when the moment for casting is reached. This starts the centrifuging, which takes about

20 seconds.

12. Turn the Multiplex melting torch off.

13. The lock will release the lid after about 15 seconds. Open lid, remove mould.

14. Switch main switch off („O“).