26

8

5

9

8

0

B

A

-e

n

/0

5

3

3

4

.0

0

1

7

1

…

English

⋅

Gelovit 200

en

Unit description

Gelovit 200

Gelovit 200 is used to melt and store gel duplicating

material. The temperature of the duplicating

material can be constantly read off an electronic

display.

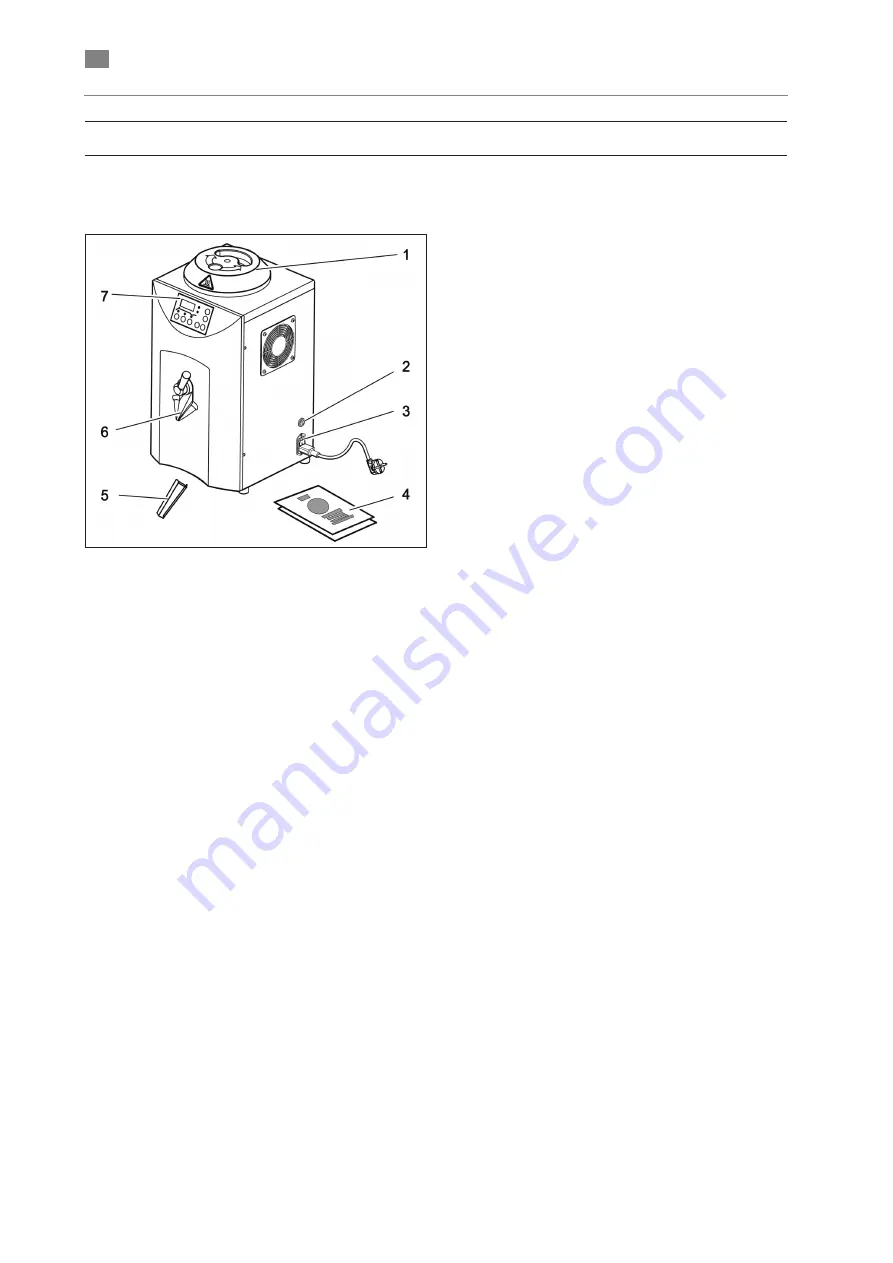

1 Lid/cover

2 Fuse

3 Main switch, mains connection

4 Documentation

5 Outlet extension

6 Outlet

7 Control panel

Lowerable operating temperature *

Gelovit 200 is equipped with an electronic temper-

ature control. The automatic melting system starts

after the duplicating material is inserted at the push

of button "T1": the material is melted and subse-

quently cooled down to the operating temperature

"T2". By pressing button "T3", the temperature can

be brought closer to the

reduced operating temper-

ature

"T3" within approx. 20 minutes and

contraction due to hardening can thus be prevented.

Because duplicating material can be kept above the

gelling temperature without clumps occurring only

for a short time, it is automatically heated up to the

operating temperature "T2" again after 10 minutes.

* Suitable for BEGO duplicating materials

Castogel

®

and Wirodouble

®

.

Provision time

The melting and cooling down of 6 kg of duplicating

material to the operating temperature takes 3 to

4 hours, depending on the duplicating material used

and the manufacturer.

Built-in timer

By means of a timer, the unit can be set for the night

so that duplicating material is available at operating

temperature at the beginning of the next working

day.

Quality assurance

Gelovit 200 makes an important contribution to

quality assurance because the number of quality-

reducing melting operations can be monitored (see

instructions on page 30…31).

Safety in the event of power failure

In the event of a temporary power failure, the micro-

processor registers the last operating mode and

continues the setting last selected. It is melted again

only when the duplication material has cooled down

below the reduced operating temperature "T3".

The temperatures are factory-set to 93°C for

melting, 42°C for processing and 39°C for working

at reduced operating temperature. The tempera-

tures can be varied and thus adapted to the dupli-

cating material used. For BEGO‘s duplicating

materials Castogel

®

and Wirodouble

®

we

recommend the factory-set temperatures. The

settings have to be changed for the BEGO dupli-

cating material Wirogel M (see “Check set tempera-

tures”, page 29).