43

860

76

D

B

-en/

03

35

5.0

00

32

English

⋅

en

Using welding wire

Often the job is to weld the workpieces through and

through into the inside. This is done by enlarging the

seam to the centre and filling with welded-in wire as

filler metal.

Recommended filler metals: see table on next page.

An alternative method is the above described

"circular deep penetration welding", which is

especially suitable for large cross-sections.

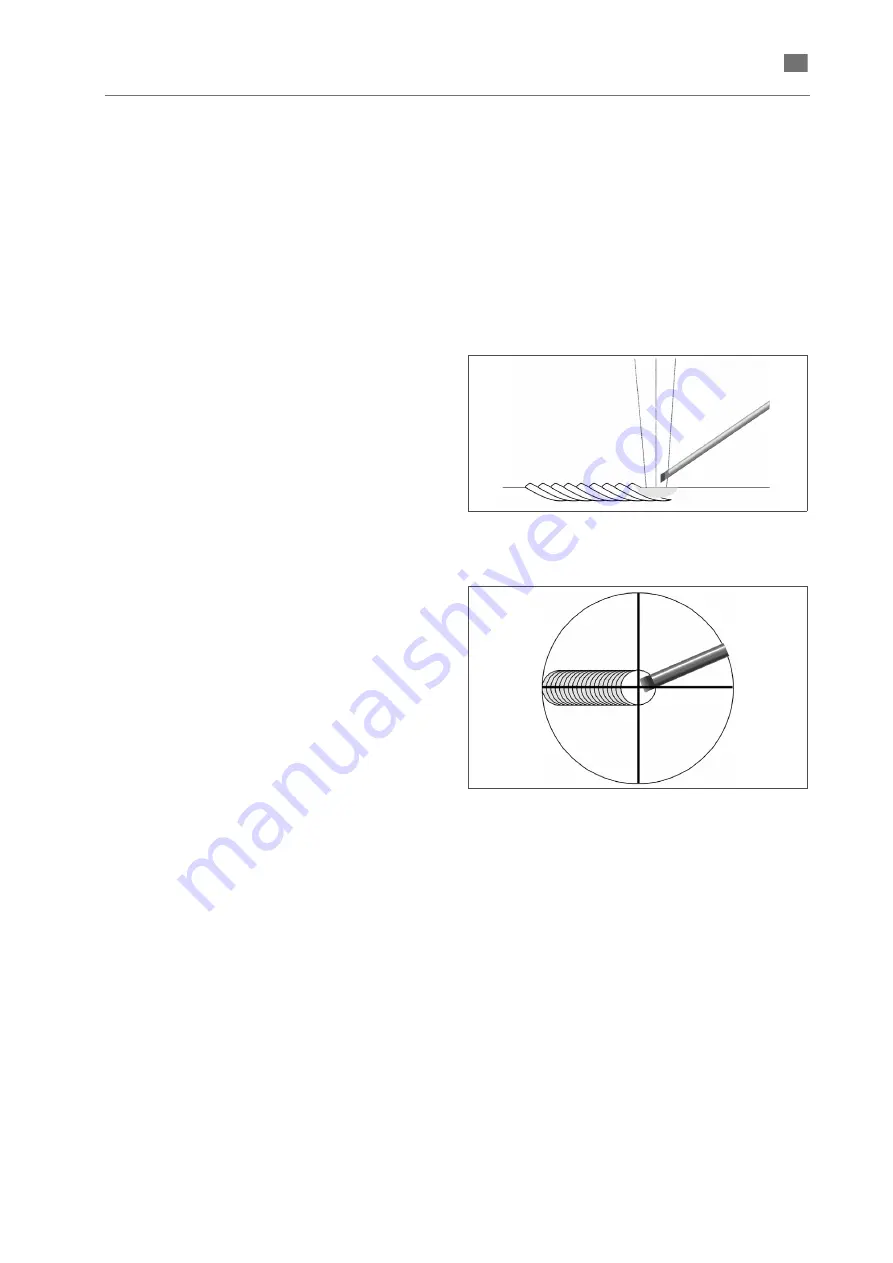

The welding wire is to be applied through the so-

called melting bath method:

•

Every laser pulse is to be directed such that

approx. 1/3 is aimed at the wire tip and approx.

2/3 at the metal surface so the metal dripping

from the wire strikes a molten surface

(Fig. 39).

•

The spot welds should overlap by approx. 80%

so the centre of the previous spot is always

covered (Fig. 40).

•

An example of welding parameters (the exact

values must be determined through tests)

Non-precious wire Wiroweld:

approx. 260 - 280 V, approx. 8 ms

Precious metal wire:

280 - 300 V, approx. 15 ms

Fig. 39

Melt welding wire and surface at the same

time

Fig. 40

Place spot welds so they overlap by approx.

80%